CONDENSTOP®

Protect Your Livestock or Dry Goods From Potential Hazards of Condensation on Metal Roof Panels

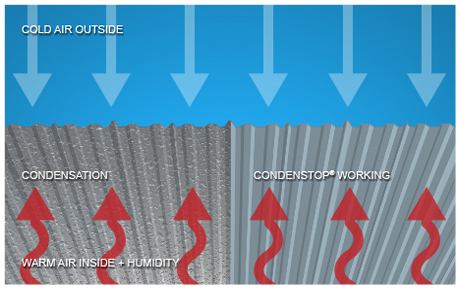

Whenever the outside temperature drops below the dew point, condensation from water vapour will inevitably form on the interior of metal roof panels. And, whether the building is used to house and protect livestock, or simply to store dry goods, condensation poses serious threats that can potentially harm the building’s valuable contents.

For more than 15 years, CondenStop® has been preventing problems caused by moisture from condensation in metal buildings and roof systems, and offers a far superior solution to blankets and retarders in protecting insulation in open metal roof systems. Installing panels enhanced with CondenStop will also save on contractor labour and equipment costs associated with common fiberglass anti-condensation blankets. Featuring the industry’s most advanced technology, CondenStop remains the market leader in keeping building insulation and contents dry.

Resources

What’s the Harm in Excess Condensation? Plenty.

Condensation, sweating and dripping can have severe, adverse effects on the health and quality of life for livestock housed in agricultural shelters, as well as on the condition of goods stored in storage facilities and hangars. Other common but inefficient solutions for condensation problems – including insulated panels, or ventilation systems – are expensive and are not, in fact, required for thermal performance, whereas CondenStop® is both economical and a highly efficient pre-emptive solution to condensation in storage facilities.

CondenStop® Eliminates Interior Roof Panel Condensation

Factory applied to roof panels by AGWAY Metals, lightweight CondenStop® offers an economical solution to prevent problems caused by condensation in metal buildings and roof systems used in agricultural, industrial and commercial buldings.

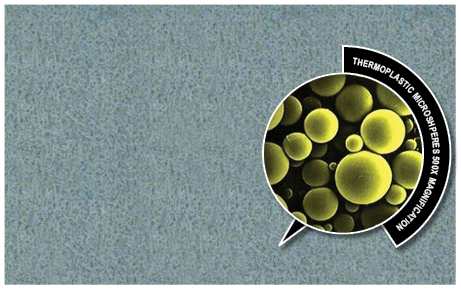

Ideal for new installations or retrofits, CondenStop employs technologically advanced layers of synthetic, nonwoven fleece, with unique Thermoplastic Microspheres, to absorb and store condensed water vapour, thereby managing/regulating interior humidity. Once the appropriate temperature and ventilation conditions return, moisture retained by CondenStop will once again evaporate into the ambient interior air through convection.

Advanced Technology is Key to CondenStop’s Efficiency

Because it exposes a very large surface area (up to 60 sq ft per each sq ft of fleece), the distribution of large and small pores in CondenStop’s creates the critical characteristics required to retain/store extraordinary volumes of moisture to prevent sweating and dripping of metal roofs. In fact, each ConenStop’s unique combination of fibers and microspheres results in an unparalleled Time-to-Drip. Just a few hours till drip formation is not sufficient, building owners and users need a drip-free, sweat-free building 24/7.

Benefits of CondenStop® from AGWAY Metals Include:

- Eliminates condensation more effectively, for less cost

- Protects livestock, assets and investments from moisture related problems

- Saves time and money vs. other vapor barrier products

- Can be used in place of traditional vapor retarders

- Increases interior corrosion protection

- Light gray color enhances the interior appearance of an open frame roofs

Performance-Tested CondenStop® is Fully Warranted Against De-lamination for 20 Years.

Testing Methodology

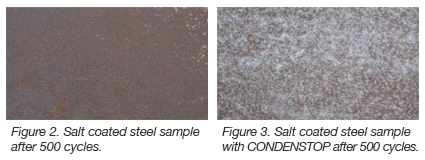

The effects of corrosion on steel panels covered with CondenStop® was evaluated through the completion of cyclic condensation tests, in which three different steel sheets were used for testing; bare mild steel; hot dip galvanized steel; and zincalume. All sheets were directly exposed to a highly salt laden exterior environment. CondenStop® was tested by adhering, as would be done in practice, to the three different steel sheet types.

By cycle changing temperature and accelerated cooling and drying in an environmental chamber, condensation was created at the surface of the samples. After 250 and 500 condensation/drying cycles, the surfaces of the steel sheets were inspected visually and with the aid of an optical microscope. A second set of specimens was then tested to simulate a marine environment. This was done by applying a salt coating to the metal sheets before applying the CondenStop® membrane.

Test Conclusions

CondenStop® does not increase the corrosion of long run steel metal, not even on the cut edges. In fact, CondenStop® helps fight corrosion, even in a severe, marine environment.