Product Sheet

![]()

Platinum HT-B Underlayment

PLATINUM HT-B is a high temperature self-adhered waterproofing membrane made with an advanced Black Butyl rubber adhesive formulation and is designed for use as secondary ice and water protection in steep slope roofing applications. It offers premium protection against water infiltration from snow, ice dams, and wind driven rain. It can be used under most primary roofing materials such as residential or commercial metal, mechanically attached concrete or clay tiles, primed cedar shakes, and asphalt or composite shingles.

Platinum HT-B combines a GRIPSPOT™ patented slip resistant walking surface with a high strength, high temperature black butyl adhesive backing that allows for both low temperature (32°F / 0°C) and rising deck adhesion and high temperature flow stability up to 265°F(129.4°C).

The GRIPSPOT™ walking surface features raised fibrous traction spots and smooth channels for shedding water. This provides faster dry times while offering unmatched slip resistance in all types of weather and surface conditions; dry, wet, frozen, and dusty. Platinum HT-B comes with a silicone treated split-release liner for ease of removal during installation.

- GRIPSPOT™ (Patent # 2,938,005) slip resistant walking surface

- Unique Black Butyl adhesive provides premium bond to plywood or OSB roof decks

- Longer shelf life 18 months +

- No VOC’s and chemically compatible with EPDM and TPO products

- Nail sealable – meets and exceeds ASTM D1970

- Low installation temperature (32°F / 0°C) and rising

- Watertight laps without special treatment or primers

- 180 day UV exposure

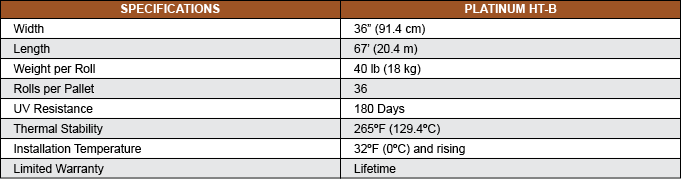

Specifications

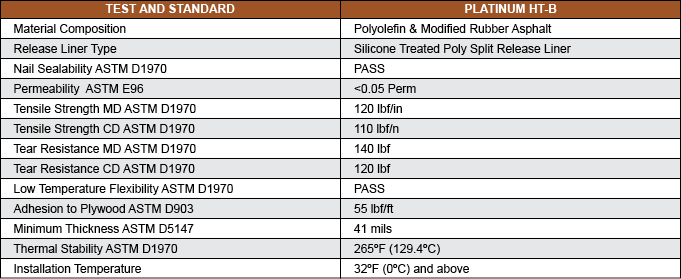

Technical Data

Installation Instruction

USE:

Platinum HTB is a high temperature, self-adhered waterproofing membrane made with an advanced black butyl rubber adhesive formulation and designed for use in steep slope roofing applications 2:12 and greater. It offers premium protection against water infiltration from snow, ice dams, and wind driven rain. Platinum HTB is designed for use under most primary roofing materials such as residential or commercial metal, mechanically attached concrete or clay tiles, primed cedar shakes, and asphalt or composite shingles.

STORAGE:

For best results store Platinum HTB upright in its original packaging in a well-ventilated area at room temperature between 40°F (4.4°C) and 90°F (32°C). If product has been stored at a high temperature above 90°F (32°C) it may become difficult to remove the release liner backing. To correct this, move product to a cooler location. Once cooled, the release liner can be easily removed.

DECK PREPARATION:

Platinum HTB should be installed over a clean, smooth, and dry deck. The deck should also not have any voids, protrusions, damaged or unsupported areas. For re-roofing projects, replace any water damaged sheathing and sweep roof deck thoroughly removing dust, dirt and loose nails. Do not install over old roof covering.

APPLICATION:

For best results Platinum HTB should be installed when the air, membrane, and substrate temperature is over 40°F (4.4°C). However, Platinum HTB can be installed in temperatures as low as 32°F (0°C) and rising. Priming is not required when attaching to wood or OSB decks. Concrete or masonry decks should be primed with a solvent or water based primer that meets ASTM D41 for self-adhesive membranes. Membrane to be applied in shingle lap fashion working from the low point to the high point of the roof. Apply the membrane in valleys before the membrane is applied to the eaves. Platinum HTB is to be laid out horizontally (parallel) to the eave with the printed side up. Horizontal overlaps to be 3” using the flat designated selvage edge. For best adhesion performance it is recommended to not overlap up onto the Gripspot walking surface. For end laps it is recommended to overlap a minimum of 6” and nail 1” in from the edge along the vertical end lap with 6” spacing between nails. To increase adhesion a water based primer can be used along end lap. End laps should be offset a minimum of 6 feet on adjacent courses. Where it is necessary to overlap Platinum HTB onto the Gripspot walking surface such as over the ridge it is recommended to cap nail along the outer edge 1” in at 6” intervals. Note if underlayment will be left exposed for an extended period in high wind areas it is also recommended to nail along the outer edges of the roof along the rake or eave.

For easier installation, it is recommended to cut the membrane into manageable lengths. Then peel back one side of the split release liner and apply in position on the roof deck and then press in place by hand or with a weighted roller to increase adhesion to the deck. Once one side has been pressed to the deck peel back the remaining half of the release liner and press down to adhere to the roof deck again using a weighted roller to increase adhesion. For improved adhesion hand rolling over the selvage edge and directly above the selvage edge using a weighted roller is recommended. If a roller is not available or not considered safe, walk on all laps, and as much of the field area as possible.

For Cold Weather Applications 32°F (0°C) or below, a primer should be used and the upper most selvage edge blind nailed using 3/8” head roofing nails 1” or longer. Space nails along edge at 12” intervals using the marked locations. For best results, allow Platinum HTB to ambiently warm to room temperature prior to application.

For Steep Slope Applications (5:12 or greater), high wind areas, or when installing at temperatures greater than 100°F (38°C), it is recommended to blind nail the selvage edge area as per above under cold weather application.

Platinum HTB should be applied under the metal drip edge along the rakes and over the metal drip edge along the eaves unless otherwise specified by local building codes. Do not fold Platinum HTB over the roof edge unless the edge is to be subsequently covered over by a drip edge or other flashing material.

In areas where ice damming can occur, install Platinum HTB from the eaves up the roof to a point not less than 24 inches inside the exterior wall, measured horizontally. Consult your local building code for specific requirements.

For valley applications, peel the release liner; center the sheet over the valley and hand press in place from the center of the valley outward. Note: It is very important Platinum HTB stay in contact with the roof deck into and out of the valley area. Platinum HTB should never be suspended or bridge a valley. It is recommended to follow up with a weighted roller or by walking on the surface. Give special attention to ALL perimeter edge areas and overlaps.

Repair holes, fish mouths, tears, and any other penetration damage to the membrane with a round patch of membrane extending passed the damaged area by 6 inches in all directions. Do not install fasteners through membrane over any unsupported areas of the structural deck, such as over joints between adjacent structural panels.

PRECAUTIONS:

Platinum HTB is a moisture and vapor barrier and therefore must be installed above a properly ventilated space(s). Follow ALL building codes applicable to your geographical region and structure type. Platinum HTB is not designed for indefinite outdoor exposure. Final roofing should be installed within 180 days of underlayment installation.

These provided Installation instructions are designed to offer recommendations to achieve best performance from our products. However, it is imperative that you follow ALL building codes or architectural specifications applicable to your geographical region and structure type.

CAUTION – Read Good Safety Practice Below

As with any roofing product, always follow safe roofing codes & practices (OSHA) and always use and wear fall protection devices when working on roofs. Release liners are slippery and should be removed from work area immediately after application. Use caution when walking or standing on Platinum HTB as slip resistance may vary with surface conditions, weather, footwear and roof pitch. Failure to use proper safety gear and footwear can result in serious injury.