Indaten™

Indaten™ Weathering Steel. A Perfect Blend of Strength and Raw Beauty

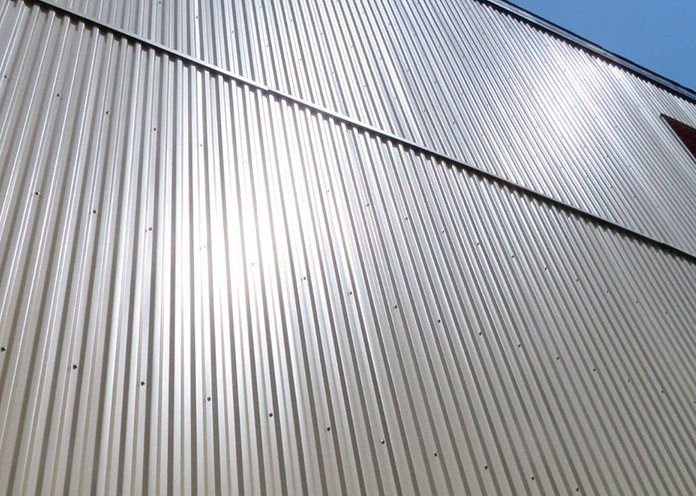

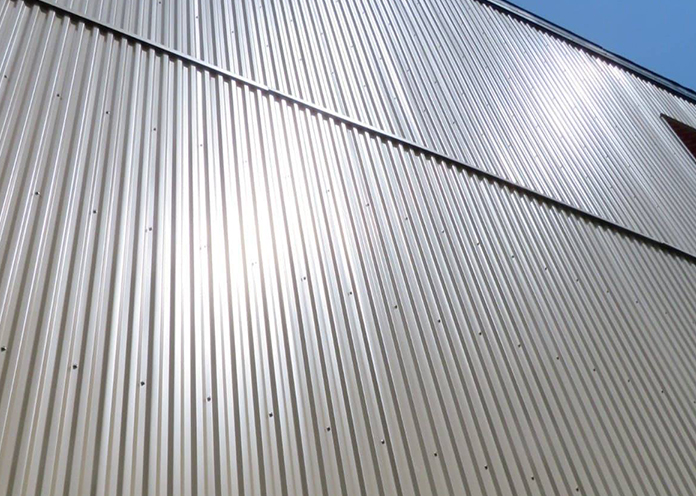

Weathering steels are versatile and intended for exterior building use in façades or roof applications seeking the modern concept that architecture and infrastructure should blend with natural and urban landscapes. In both new and refurbishment projects, weathering steels create an innovative and unique aspect. Weathering steel for cladding can be shaped into a wide range of geometries, including roll formed and single sheet panels.

Using decades of experience with corrosion resistance mechanisms, ArcelorMittal has developed a cold rolled weathering grade known as Indaten™ for steel building panels that will satisfy the requirements of ASTM A606 Type 4.

Development of the Patina

A unique aspect of weathering steels is the exposed surface changes over time. It transitions from its initial dark grey mill finish to an orange patina in a matter of weeks. The patina continues to evolve, reaching its final dark brown colour after several years – dependent on local weather conditions. Its distinct brownish, non-uniform patina, with coarse texturing, means weathering steel will integrate perfectly into both urban and natural environments.

For the best results weathering steels must be exposed to alternating wet/dry cycles, with no permanent wet or damp conditions, such as contact with stagnant water, constant humidity, sheltered damp locations, soil or covered by vegetation. Aggressive atmospheres, such as distances within two kilometres of coastal waters, should be avoided as the high concentrations of chlorides are detrimental to the patina layer leading to an increased rate of corrosion. Atmospheric pollution and industrial fumes, particularly sulfur dioxide, will also negatively affect the patina and increase the corrosion rate.

During patina formation on weathering steel, small amounts of corrosion products (rust) are washed out by rainfall. The amount of corrosion product leached out by rainfall diminishes over time, but never stops completely and can lead to staining of neighbouring material. Special design considerations for the structure are needed to ensure that any discoloured rainwater is properly collected and directed away from exposed surfaces. The corrosion product consists mainly of stable iron oxide which is not harmful to the environment, vegetation or wildlife.

Measurement Type

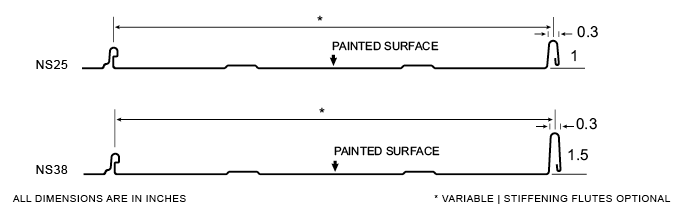

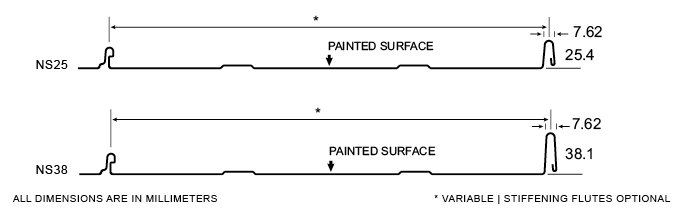

Nail Strip

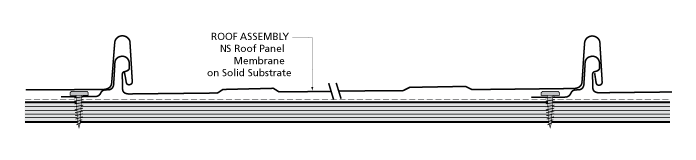

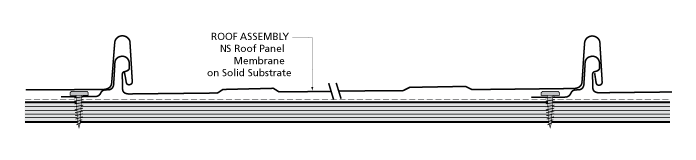

Agway’s Nail Strip panel system offers variable panel widths, two rib heights and easy installation, making it the ideal choice for seasoned contractors or do-it-yourselfers. Using a continuous nail strip that requires no seamer, Agway’s Nail Strip systems facilitate easy installation, making them a popular choice for residential, agricultural or commercial projects.

Whether you choose a profile from our Nail Strip, Standing Seam, or Snap Lock roof cladding systems, the result will be a stunning, architecturally distinctive roof that installs easily and has no exposed fasteners. All these durable Agway roof cladding products are available in a full range of stock colours, in variable panel widths, and with optional stiffening flutes. All require a single skin application and must be applied over a solid substrate and waterproof membrane. Knee Caps are also available (same changes as above).

Resources

Measurement Type

Profile Picture

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Continuous nail strip

- Knee Caps available

- No seamer required

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| NS 25 | 3/12 – 12/12 | 0.0236” | 2′ 6″ – 45′ | 10″ – 28″ |

| NS38 | 1.5/12 – 12/12 | 0.0236” | 2′ 6″ – 45′ | 10″ – 28″ |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For NS25 or NS38 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 48”

Standard Panel Widths

| GAUGE | NS25 | NS38 |

|---|---|---|

| 24 | 19.56″ | 18.56″ |

Oil Canning

- Oil Canning is a naturally occurring phenomenon inherent in all sheet metal

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Fasteners at maximum 2′ centres

- Snap-in-place design

Side Lap Detail

Overlap Construction

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Continuous nail strip

- Knee Caps available

- No seamer required

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| NS 25 | 3/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

| NS38 | 1.5/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For NS25 or NS38 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 1,219 mm

Standard Panel Widths

| GAUGE | NS25 | NS38 |

|---|---|---|

| 24 | 497 mm | 471 mm |

Oil Canning

- Oil Canning is a naturally occurring phenomenon inherent in all sheet metal

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Fasteners at maximum 2′ centres

- Snap-in-place design

Side Lap Detail

Overlap Construction

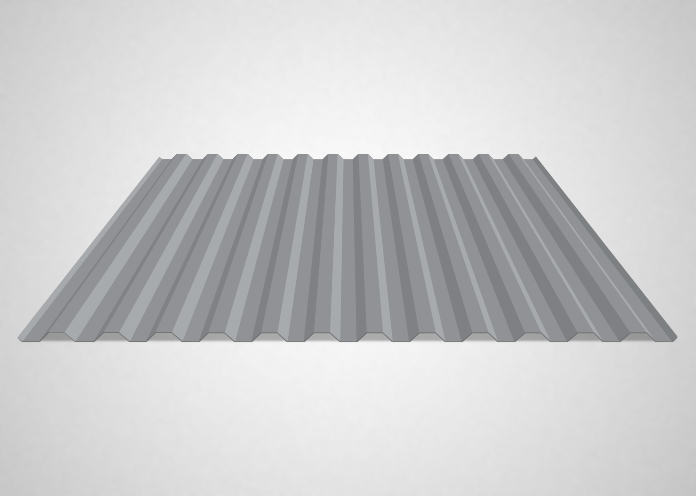

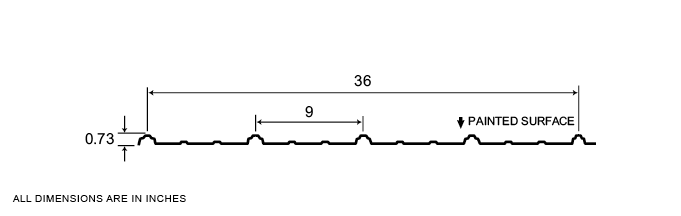

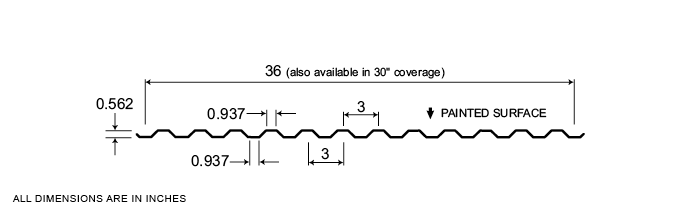

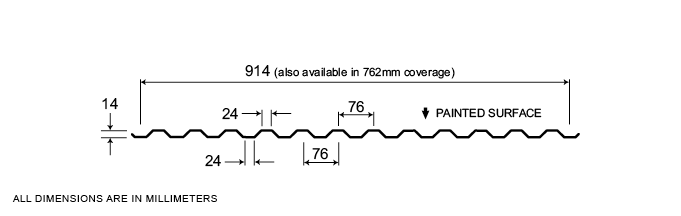

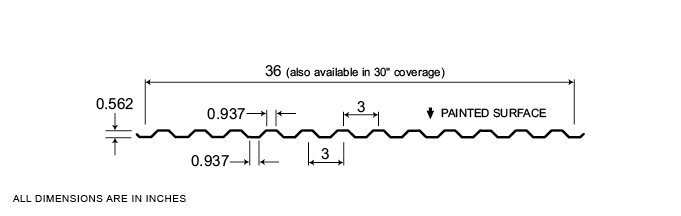

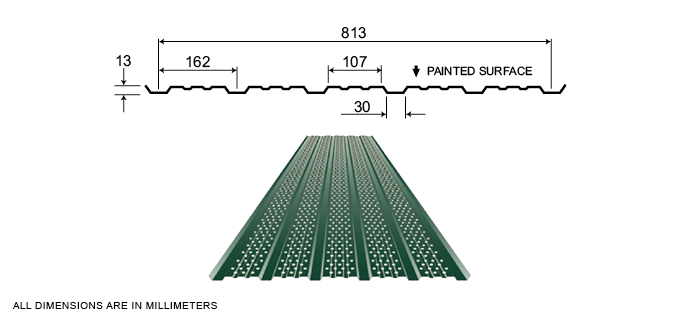

Optimum Rib

A very popular profile for roof applications, our economical, easy-to-install, Optimum Rib lightweight panels add a professionally finished look to the exterior of any structure. Available in a wide range of colours, Agway’s Optimum Rib profile, combined with available trims, vents, fasteners and other accessories provides a complete roofing solution for any project.

Measurement Type

Profile Picture

- Steel conforms to ASTM A653.

- Section properties are in accordance with CSA-S136-07.

- Values in row “S” are based on strength.

- Values in row “D” are based on a deflection limit of 1/180 of the span.

- Web crippling not included in strength values. See example calculation in notes to designer.

- Contact the sales department for stocked colours and gauges.

- The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural

- Engineering, University of Waterloo, Ontario, Canada.

- Steel conforms to ASTM A653.

- Section properties are in accordance with CSA-S136-07.

- Values in row “S” are based on strength.

- Values in row “D” are based on a deflection limit of 1/180 of the span.

- Web crippling not included in strength values. See example calculation in notes to designer.

- Contact the sales department for stocked colours and gauges.

- The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural

- Engineering, University of Waterloo, Ontario, Canada.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 30 | 780 | 36 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 762 | 1981 | 915 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0135 | 0.71 | 80 | 0.0126 | 0.0099 | 0.0083 |

| 0.0180 | 0.93 | 33 | 0.0167 | 0.0144 | 0.0110 |

| 0.0240 | 1.22 | 33 | 0.0220 | 0.0198 | 0.0146 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.343 | 3.46 | 550 | 0.676 | 0.533 | 0.0113 |

| 0.457 | 4.52 | 230 | 0.895 | 0.772 | 0.0150 |

| 0.610 | 5.94 | 230 | 1.18 | 1.07 | 0.0199 |

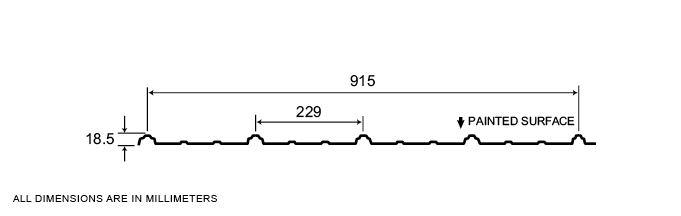

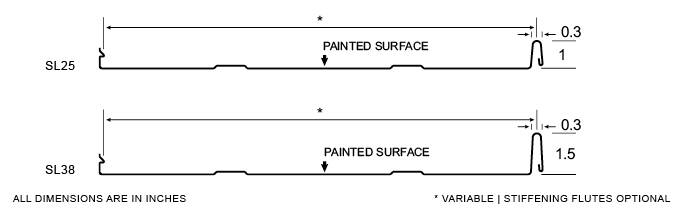

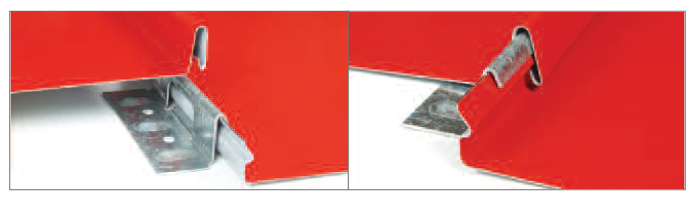

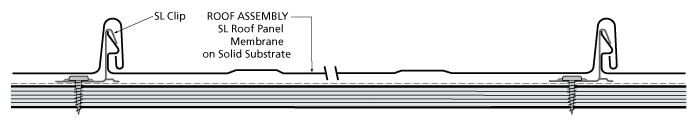

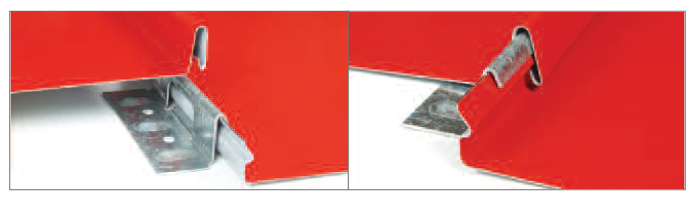

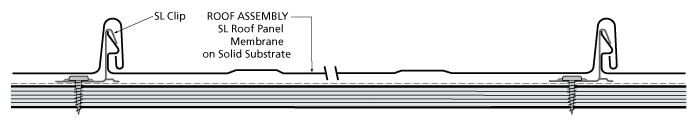

Snap Lock

Designed for its ease of installation, Agway’s Snap Lock panel system offers variable width panels that install easily – just attach the hold down clip along the panel rib and snap each panel into the previous one. Featuring hidden clips with no exposed fasteners, like Nail Strip, Agway’s Snap Lock Profile is easy to install and, making it a popular choice for a wide range of residential, agricultural or commercial projects.

Whether you choose a profile from our Snap Lock, Standing Seam, or Nail Strip roof cladding systems, the result will be a stunning, architecturally distinctive roof that installs easily and has no exposed fasteners. All these durable Agway roof cladding products are available in a full range of stock colours, in variable panel widths, and with optional stiffening flutes. All require a single skin application and must be applied over a solid substrate and waterproof membrane, using clips at a maximum of 2’ centres. Knee Caps are also available (same changes).

Resources

Measurement Type

Profile Picture

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Hidden clips for easy installation

- Knee Caps available

- No seamer required

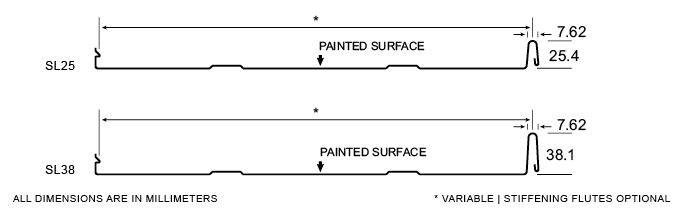

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| SL25 | 3/12 – 12/12 | 0.0236″ | 2′ 6″ – 45′ | 10″ – 28″ |

| SL38 | 1.5/12 – 12/12 | 0.0236 | 2′ 6″ – 45′ | 10″ – 28″ |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Clips at maximum 2’ centers – 2 fasteners per clip

- Snap-in place design

Standard Panel Widths

| GAUGE | SL25 | SL38 |

|---|---|---|

| 24 | 20.81″ | 19.31″ |

Hold-Down Clip Detail

Sheet Overlap Detail w/Hold-down

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Hidden clips for easy installation

- Knee Caps available

- No seamer required

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| SL25 | 3/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

| SL38 | 1.5/12 – 12/12 | 0.610 mm | 0.76 – 13.71 m | 254 – 711 mm |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that this be applied over waterproof membrane

- Clips at maximum 0.61 m centers – 2 fasteners per clip

- Snap-in place design

Standard Panel Widths

| GAUGE | SL25 | SL38 |

|---|---|---|

| 24 | 529 mm | 490 mm |

Hold-Down Clip Detail

Sheet Overlap Detail w/Hold-down

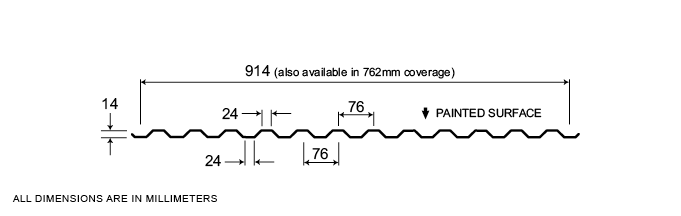

Ultima

Ideal for projects requiring a slightly different style while maintaining a more traditional feel. The multi-ribbed design not only provides a more unique aesthetic appeal, but delivers a more organic overall feel as well.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 36" | 480" | 36" |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 914 mm | 12.192 m | 914 mm |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0150 | 0.73 | 80 | 0.0616 | 0.0616 | 0.0181 |

| 0.0180 | 0.92 | 33 | 0.0429 | 0.0429 | 0.0136 |

| 0.0240 | 1.22 | 33 | 0.0616 | 0.0616 | 0.0181 |

| 0.0300 | 1.53 | 33 | 0.0758 | 0.0758 | 0.0226 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.381 | 3.56 | 550 | 3.310 | 3.310 | 0.0248 |

| 0.457 | 4.45 | 230 | 2.309 | 2.309 | 0.0186 |

| 0.610 | 5.94 | 230 | 3.310 | 3.310 | 0.0248 |

| 0.762 | 7.42 | 230 | 4.077 | 4.077 | 0.0308 |

LEEDV4

LEEDV4 and Steel

Designers and builders have long recognized steel for its strength, durability and functionality. An important aspect of steel’s story is its high recycled content and end-of-life recovery rate. Both attributes are recognized by the U.S. Green Building Council’s (USGBC) green building rating system, Leadership in Energy and Environmental Design (LEED), but steel construction products can contribute to many other LEED credits as well, either directly or indirectly.

USGBC’s latest version, LEEDv4, includes a completely revised and expanded Materials and Resources section, with new credits in the areas of life-cycle assessment (LCA), environmental product declarations (EPDs), and overall product transparency.

How Can Steel Contribute to a LEED V4 Project?

Steel is dimensionally stable and can be fabricated to exact specifications to minimize on-site waste. Its benefits include high strength, durability, material reduction through integrated design, recyclability, decreased maintenance cost and potential adaptive reuse. Steel construction products typically emit no volatile organic compounds (VOCs) on site, which contributes to better indoor air quality. The steel construction products industry has developed a wide range of EPDs which can assist project teams in evaluating environmental life cycle impacts.

This fact sheet explores the potential benefits steel construction products can provide to a project seeking LEED certification in accordance with the requirements of LEEDv4 for Building Design and Construction. (NOTE: The italicized text below represents selected excerpts from individual credits within LEEDv4, while commentary is shown in non-italicized, indented text. Please see the official LEEDv4 document for the complete text of these credits.)

Sustainable Sites (SS)

SS Credit: Site Development – Protect or Restore Habitat (1-2 Points)

Intent: Preserve and protect from all development and construction activity 40% of the greenfield area on the site (if such areas exist).

- Steel structures and steel components are often manufactured with much of the construction process occurring away from the project site. Reducing the amount of time spent onsite and reducing the need for onsite fabrication may decrease the likelihood of site disturbance.

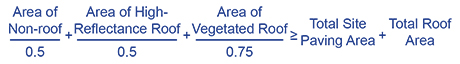

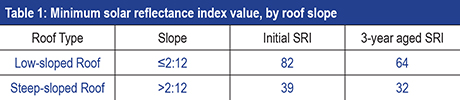

SS Credit: Heat Island Reduction (1-2 Points)

Intent: To minimize effects on microclimates and human and wildlife habitats by reducing heat islands.

Option 1: Non-roof and Roof (2 points except Healthcare, 1 point Healthcare)

Meet the following criterion:

Alternatively, an SRI and SR weighted average approach may be used to calculate compliance.

High-Reflectance Roof

Use roofing materials that have an SRI equal to or greater than the values in Table 1. Meet the three-year aged SRI value. If three-year aged value information is not available, use materials that meet the initial SRI value.

Option 2: Parking under Cover (1 point)

Place a minimum of 75% of parking spaces under cover. Any roof used to shade or cover parking must (1) have a three-year aged SRI of at least 32 (if three-year aged value information is not available, use materials with an initial SRI of at least 39 at installation).

- Many steel roofing products are available that meet the solar reflectance and/or SRI criteria in this credit, resulting in reduced cooling loads and lower utility bills. Some of these products utilize reflective pigment technology, which allows for a wider range of colors that meet the LEEDv4 requirements. See Cool Metal Roofing for information on cool metal roofing products. Click here for a complete list of initial and 3-year-aged solar reflectance values for specific steel roof products.

Energy and Atmosphere (EA)

EA Prerequisite: Minimum Energy Performance (Required)

EA Credit: Optimize Energy Performance (1-20 Points)

Intent: To achieve increasing levels of energy performance beyond the prerequisite standard to reduce environmental and economic harms associated with excessive energy use.

- Because of its dimensional stability, properly designed steel framing can contribute to an exceptionally tight building envelope, resulting in reduced air loss and better building energy performance over time.

EA Credit: Renewable Energy Production (1-3 Points)

- Steel roofs provide an excellent platform for solar photovoltaic (PV) systems because their expected lifespan equals or exceeds the 20- to 30-year expected life of typical solar PV panels. Additionally, proprietary connection and framing systems are available for mounting PV panels directly to the standing seams of steel roofing panels, eliminating the need for roof penetration attachments.

Materials and Resources (MR)

MR Prerequisite: Construction and Demolition Waste Management Planning

Intent: To reduce construction and demolition waste disposed of in landfills and incineration facilities by recovering, reusing, and recycling materials.

- Steel construction products can be manufactured and/or fabricated to precise specifications, resulting in minimal job site scrap, all of which can be easily recycled through the existing infrastructure of readily-available scrap processing facilities.

MR Credit: Building Life Cycle Impact Reduction (2-6 Points)

Intent: To encourage adaptive reuse and optimize the environmental performance of products and materials.

Option 1: Historic Building Reuse

Option 2: Renovation of Abandoned or Blighted Building

Option 3: Building and Material Reuse

- The long-life durable nature of steel buildings makes them particularly suitable for renovation and reuse. Bolted or screwed connections present little challenge to disassembly, and welded connections can be cut without distorting or severely limiting reuse of the remaining members. Steel framing systems can provide long spans and large column-free spaces that are adaptable and flexible, and steel partitions can be easily relocated to new positions within the building.

Option 4: Whole Building Life Cycle Assessment (3 points)

For new construction (buildings or portions of buildings), conduct a life-cycle assessment of the project’s structure and enclosure that demonstrates a minimum of 10% reduction, compared with a baseline building, in at least three of the six impact categories listed below, one of which must be global warming potential. No impact category assessed as part of the life-cycle assessment may increase by more than 5% compared with the baseline building.

- In addition to environmental product declarations (EPDs), life cycle inventory (LCI) data is available for nearly all steel construction products, allowing designers to easily complete the whole building life cycle assessment (LCA) process as required by this credit. LCI data for semi-finished steel products (including hot-rolled structural sections and cold-formed steel framing) is available at the Steel Recycling Institute.

MR Credit: Building Product Disclosures and Optimization – Environmental Product Declarations (1-2 Points)

Option 1: Environmental Product Declaration (EPD) (1 point)

Use at least 20 different permanently installed products sourced from at least five different manufacturers that meet one of the disclosure criteria below.

- Product-specific declaration

- Products with a publicly available, critically reviewed life-cycle assessment conforming to ISO 14044 that have at least a cradle to gate scope are valued as one quarter (1/4) of a product for the purposes of credit achievement calculation.

- Environmental Product Declarations which conform to ISO 14025, 14040, 14044, and EN 15804 or ISO 21930 and have at least a cradle to gate scope.

- Industry-wide (generic) EPD — Products with third-party certification (Type III), including external verification, in which the manufacturer is explicitly recognized as a participant by the program operator are valued as one half (1/2) of a product for purposes of credit achievement calculation.

- Product-specific Type III EPD — Products with third-party certification (Type III), including external verification in which the manufacturer is explicitly recognized as the participant by the program operator are valued as one whole product for purposes of credit achievement calculation.

- USGBC approved program – Products that comply with other USGBC approved environmental product declaration frameworks.

Option 2: Multi-Attribute Optimization (1 point)

Use products that comply with one of the criteria below for 50%, by cost, of the total value of permanently installed products in the project. Products will be valued as below.

- Third party certified products that demonstrate impact reduction below industry average in at least three of the following categories are valued at 100% of their cost for credit achievement calculations.

- global warming potential (greenhouse gases), in CO2e;

- depletion of the stratospheric ozone layer, in kg CFC-11;

- acidification of land and water sources, in moles H+ or kg SO2;

- eutrophication, in kg nitrogen or kg phosphate;

- formation of tropospheric ozone, in kg NOx, kg O3 eq, or kg ethene; and

- depletion of nonrenewable energy resources, in MJ.

- USGBC approved program — Products that comply with other USGBC approved multi-attribute frameworks.

For credit achievement calculation, products sourced (extracted, manufactured, purchased) within 100 miles (160 km) of the project site are valued at 200% of their base contributing cost.

Structure and enclosure materials may not constitute more than 30% of the value of compliant building products.

- Environmental Product Declarations (EPDs) can be valuable tools for designing environmentally responsible buildings. An EPD is a summary of the results of a life cycle assessment (LCA), which describes the environmental impacts of products in a number of specific categories. Industry-wide EPDs are available for most major categories of North American steel construction products, including cold-formed steel framing (studs and track), structural steel and steel plate, primary and secondary steel frames, steel floor and roof deck, steel joists, and steel roofing and wall cladding products. A list of industry-wide steel product EPDs can be found here. In addition to these industry-wide EPDs, many manufacturers have published product-specific EPDs that may meet the requirements of Option 2.

MR Credit: Building Product Disclosure and Optimization – Sourcing of Raw Materials (1-2 Points)

Intent: To encourage the use of products and materials for which life cycle information is available and that have environmentally, economically, and socially preferable life cycle impacts. To reward project teams for selecting products verified to have been extracted or sourced in a responsible manner.

Option 1: Raw Material Source and Extraction Reporting (1 point)

- Products contributing to this credit must have a self-declared report (valued at ½ of a product) or a third-party verified report (valued as a full product) that describes the environmental impacts of extraction operations and activities associated with the manufacturer’s product and the product’s supply chain, using one of the corporate sustainability report (CSR) frameworks listed in the credit, such as the Global Reporting Initiative (GRI). Several North American steel producers publish such CSR reports annually. Contact specific steel producers for a copy of their CSR report.

Option 2: Leadership Extraction Practices (1 point)

Use products that meet at least one of the responsible extraction criteria below for at least 25%, by cost, of the total value of permanently installed building products in the project.

- Extended producer responsibility

- Bio-based materials

- Wood products

- Materials reuse

- Recycled content – Recycled content is the sum of post-consumer recycled content plus one-half the pre-consumer recycled content, based on cost. Products meeting recycled content criteria are valued at 100% of their cost for the purposes of credit achievement calculation.

- USGBC approved program – Other USGBC approved programs meeting leadership extraction criteria.

Structure and enclosure materials may not constitute more than 30% of the value of compliant building products.

- All steel structures and steel construction products contain significant levels of recycled content. Additionally, many steel products recovered from demolition or refurbishment projects are suitable for reuse. The LEEDv4 Reference Guide (page 535) allows a default value of 25 percent post-consumer recycled content for any steel product. However, some steel products (e.g. structural sections and reinforcing bar) may have recycled content levels as high as 100%. These higher values may be used in the LEED credit calculations if company-specific recycled content information is available from the steel product supplier. As described in the LEEDv4 Reference Guide (page 536), industry-wide or national average recycled content values may not be used in calculations to support achievement of this credit.

MR Credit: Building Product Disclosure and Optimization – Material Ingredients (1-2 Points)

Option 1: Material Ingredient Reporting (1 point)

Use at least 20 different permanently installed products from at least five different manufacturers that use any of the following programs to demonstrate the chemical inventory of the product to at least 0.1% (1000 ppm).

- Manufacturer Inventory

- Health Product Declaration

- Cradle to Cradle

- Declare

- ANSI/BIFMA e3 Furniture Sustainability Standard

- Cradle to Cradle Material Health Certificate

- USGBC approved program

And/Or

Option 2: Material Ingredient Optimization (1 point)

Use products that document their material ingredient optimization using the paths below for at least 25%, by cost, of the total value of permanently installed products in the project.

- GreenScreen v1.2 Benchmark

- Cradle to Cradle Certified

- International Alternative Compliance Path – REACH Optimization

- USGBC approved program

And/Or

Option 3: Product Manufacturer Supply Chain Optimization (1 point)

- This credit encourages the disclosure of comprehensive ingredient information (Option 1 – 1 point) and optimization of these ingredients (Option 2 – 1 additional point) for a specified number of products. The credit generally applies to end-use products as delivered to the jobsite. Option 1 can be achieved by developing a “… publicly available inventory of all ingredients identified by name and Chemical Abstract Service Registration Number (CASRN)”. Additional compliance options for Option 1 include a Health Product Declaration (HPD), Cradle to Cradle certification, and the Declare label. Compliance with Option 2 requires material ingredient optimization using the GreenScreen v1.2 Benchmark, Cradle to Cradle certification (at higher levels than Option 1), REACH Optimization, or other USGBC approved program. Some steel construction products have met the requirements of Option 1 and/or Option 2, and many others are in the process of meeting these requirements. Contact the specific steel product manufacturer for currently available information.

MR Credit: Design for Flexibility (1 Point, Applies to Healthcare Only)

Intent: Conserve resources associated with the construction and management of buildings by designing for flexibility and ease of future adaptation and for the service life of components and assemblies.

- Cold-formed steel partitions can easily be removed, reused, and/or relocated as part of a building modification. Structural steel framing can be easily modified for changes in loading requirements and/or changes to intended use or occupancy.

MR Credit: Construction and Demolition Waste Management (1-2 Points)

Option 1. Diversion (1–2 points)

Path 1. Divert 50% and Three Material Streams (1 point)

Divert at least 50% of the total construction and demolition material; diverted materials must include at least three material streams.

Or

Path 2. Divert 75% and Four Material Streams (2 points)

Divert at least 75% of the total construction and demolition material; diverted materials must include at least four material streams.

Or

Option 2. Reduction of Total Waste Material (2 points)

Do not generate more than 2.5 pounds of construction waste per square foot (12.2 kilograms of waste per square meter) of the building’s floor area.

- Steel products can nearly always make a significant contribution to this credit. Relative to Option 2, most steel construction products are manufactured or pre-cut to finished size, or fabricated to precise project specifications, prior to shipment to the jobsite. This results in minimal jobsite steel waste, such that steel contributes very little to the 2.5 pounds per square foot limit.

- Alternatively, if Option 1 is chosen as the target for compliance with this credit, 100% of the steel scrap generated at the jobsite can be easily and economically recycled, so that steel can be a positive contributor to either Path 1 or Path 2.

Measurement Type

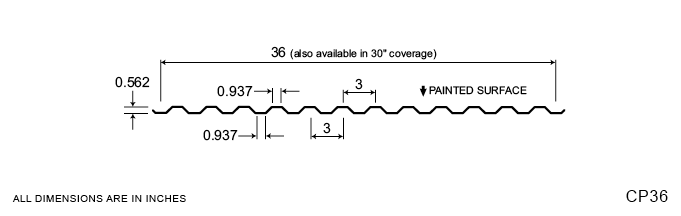

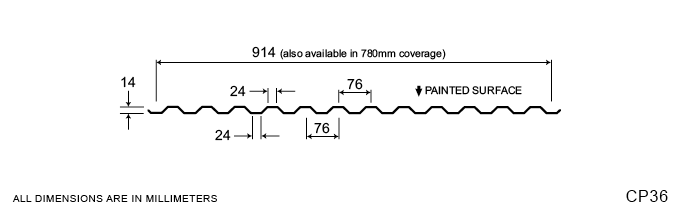

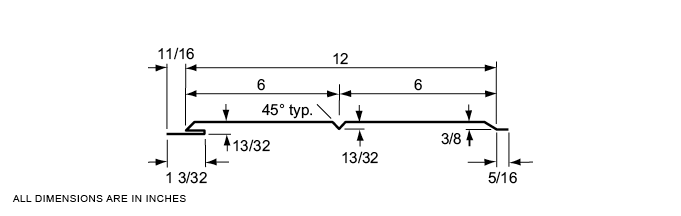

Concrete Form CP36

Agway’s CP-36 profile is ideal for concrete form applications in situations where the traditional deck profiles simply are not suitable and a more unique solution is required.

Measurement Type

Profile Picture

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 36" | 480" | 30" |

| 28 | 22 | 36" | 480" | 36" |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 914 mm | 1,219.2 cm | 762 mm |

| 28 | 22 | 914 mm | 1,219.2 cm | 914 mm |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0180 | 0.92 | 33 | 0.0432 | 0.0432 | 0.0137 |

| 0.0240 | 1.22 | 33 | 0.0616 | 0.0616 | 0.0181 |

| 0.0300 | 1.53 | 33 | 0.0759 | 0.0759 | 0.0226 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.457 | 4.45 | 230 | 2.320 | 2.320 | 0.0187 |

| 0.610 | 5.94 | 230 | 3.310 | 3.310 | 0.0248 |

| 0.762 | 7.42 | 230 | 4.080 | 4.080 | 0.0309 |

Ultima

Ideal for projects requiring a slightly different style while maintaining a more traditional feel. The multi-ribbed design not only provides a more unique aesthetic appeal, but delivers a more organic overall feel as well.

Measurement Type

Profile Picture

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 36" | 480" | 36" |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 914 mm | 12.192 m | 914 mm |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0150 | 0.73 | 80 | 0.0616 | 0.0616 | 0.0181 |

| 0.0180 | 0.92 | 33 | 0.0429 | 0.0429 | 0.0136 |

| 0.0240 | 1.22 | 33 | 0.0616 | 0.0616 | 0.0181 |

| 0.0300 | 1.53 | 33 | 0.0758 | 0.0758 | 0.0226 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.381 | 3.56 | 550 | 3.310 | 3.310 | 0.0248 |

| 0.457 | 4.45 | 230 | 2.309 | 2.309 | 0.0186 |

| 0.610 | 5.94 | 230 | 3.310 | 3.310 | 0.0248 |

| 0.762 | 7.42 | 230 | 4.077 | 4.077 | 0.0308 |

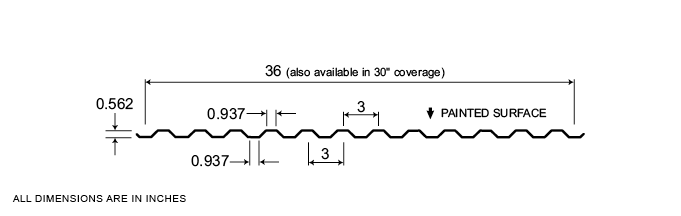

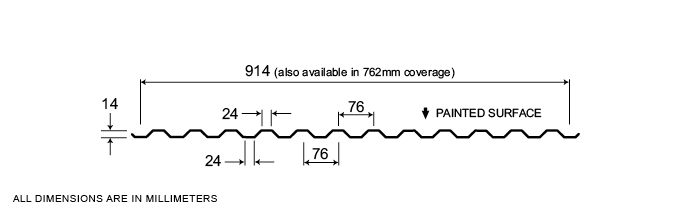

Ultima

Ideal for projects requiring a slightly different style while maintaining a more traditional feel. The multi-ribbed design not only provides a more unique aesthetic appeal, but delivers a more organic overall feel as well.

Measurement Type

Profile Picture

- Steel conforms to ASTM A653.

- Section properties are in accordance with CSA-S136-07.

- Values in row “S” are based on strength.

- Values in row “D” are based on a deflection limit of 1/180 of the span.

- Web crippling not included in strength values. See example calculation in notes to designer.

- Contact the sales department for stocked colours and gauges.

- The load table contained on this data sheet was prepared by XRS Engineered Solutions Inc., Burlington, Ontario, Canada.

- Steel conforms to ASTM A653.

- Section properties are in accordance with CSA-S136-07.

- Values in row “S” are based on strength.

- Values in row “D” are based on a deflection limit of 1/180 of the span.

- Web crippling not included in strength values. See example calculation in notes to designer.

- Contact the sales department for stocked colours and gauges.

- The load table contained on this data sheet was prepared by XRS Engineered Solutions Inc., Burlington, Ontario, Canada.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 36" | 480" | 36" |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 28 | 22 | 914 mm | 12.192 m | 914 mm |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0150 | 0.73 | 80 | 0.0616 | 0.0616 | 0.0181 |

| 0.0180 | 0.92 | 33 | 0.0429 | 0.0429 | 0.0136 |

| 0.0240 | 1.22 | 33 | 0.0616 | 0.0616 | 0.0181 |

| 0.0300 | 1.53 | 33 | 0.0758 | 0.0758 | 0.0226 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.381 | 3.56 | 550 | 3.310 | 3.310 | 0.0248 |

| 0.457 | 4.45 | 230 | 2.309 | 2.309 | 0.0186 |

| 0.610 | 5.94 | 230 | 3.310 | 3.310 | 0.0248 |

| 0.762 | 7.42 | 230 | 4.077 | 4.077 | 0.0308 |

Stratus Residential Wall Cladding

Features:

- Manufactured in 26 Ga

- Custom lengths 12” to 384” (305 mm to 9.754 m)

- Concealed nailing strip with 3/4” x 3/16” Screw Slots on 2 1/2” centres (19.1 mm x 4.8 mm Screw Slots on 63.5 mm centres)

- Hidden fastener installation – secure with #10 x 1” Pancake Head screws Fasten in centre of slots – do not over-tighten

Applications:

- Accent Panel

- Vertical Wall Installation

- Horizontal Wall Installation

Note(s):

- Oil canning may be present due to various factors

- Oil canning is not a valid reason for rejection of this product

Measurement Type

Profile Picture

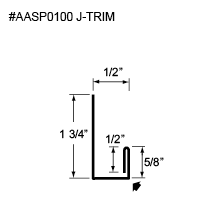

Stratus Flashing

Stratus Flashing

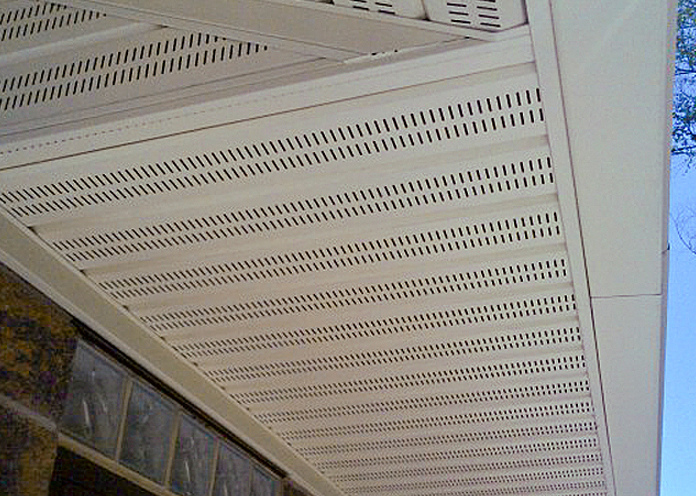

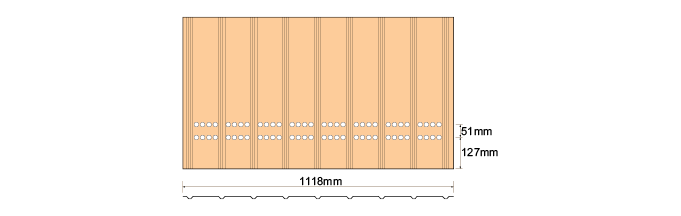

Agricultural Soffits

Introduction

Easy to handle and install, Agway V-Rib Soffits, CH5-32 Vented Soffits and Agri Soffit panels in 26 or 29 gauge, are available in rollformed or custom lengths up to 10 ft., in a variety of finishes or colours.

Measurement Type

Profile Picture

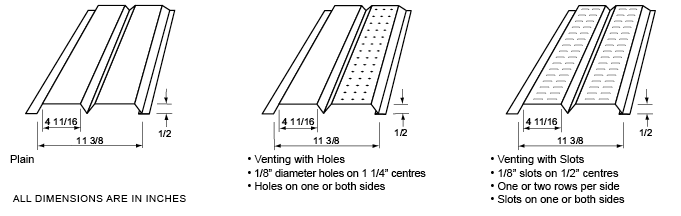

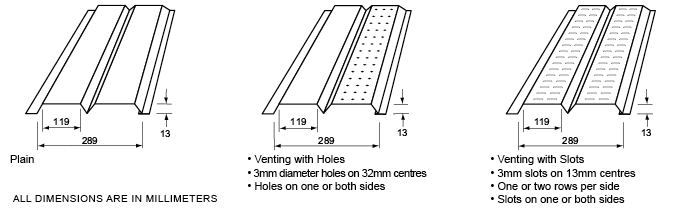

V-Rib Soffit Panels

- Custom lengths from 1’-0” to 12’-0”

- Perforated in lengths up to 12’-0”

- Available in 29, 26 and 24 ga.

- Venting available in round or slotted holes

- Stiffener Ribs available in V-Rib or Bubble Rib Maximum length: V-Rib: 12’ – 0”, Bubble Rib: 10’ – 0”

- Prepainted Steel, Aluminum, Copper, Stainless Steel and Zinc

- Precut to required length – no field cutting

- Attractive appearance

- Easy installation – secure with screws or nails to underside of overhang

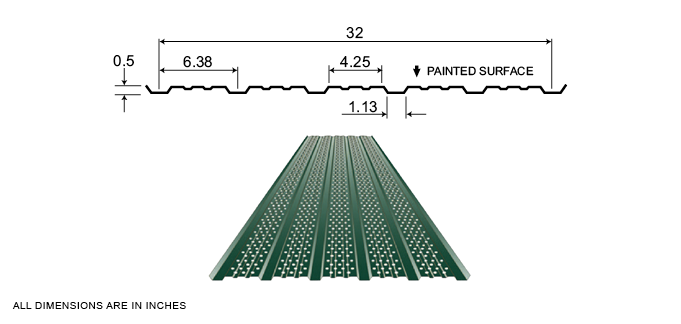

Vented Soffit CH5-32

- Rollform lengths from 0’-10” to 45’-0”

- Continuously vented on top face 1/8” dia. holes on 3/8” centres

- Stocked in 26 ga. prepainted steel QC28317 White White

- Other colours available upon request. Contact our estimating department for details

- Excellent free air area of 6%

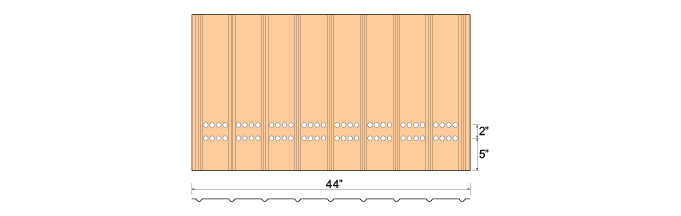

Soffit Panels

- Manufactured from 26 or 29 ga. Prepainted Steel

- Prepainted Steel, Aluminum, Copper, Stainless Steel and Zinc

- Custom lengths up to 10’

- Precut to required length – no field cutting

- Attractive appearance

- Easy installation – secure with screws or nails to underside of overhang

Applications

- Non-vented: To cover underside of building overhang (soffit)

- Vented: To allow outside air to enter the building and create cross-ventilation

- Venting available in round or slotted holes

- Use in conjunction with roof ventilators

V-Rib Soffit Panels

- Custom lengths from 305 mm to 3.7 m

- Perforated in lengths up to 3.7 m

- Available in 29, 26 and 24 ga.

- Venting available in round or slotted holes

- Stiffener Ribs available in V-Rib or Bubble Rib Maximum length: V-Rib: 3.7 m, Bubble Rib: 3.1 m

- Prepainted Steel, Aluminum, Copper, Stainless Steel and Zinc

- Precut to required length – no field cutting

- Attractive appearance

- Easy installation – secure with screws or nails to underside of overhang

Vented Soffit CH5-32

- Rollform lengths from 254 mm to 13.7 m

- Continuously vented on top face 3 mm dia. holes on 9.5 mm centres

- Stocked in 26 ga. prepainted steel QC18317 White White

- Other colours available upon request. Contact our estimating department for details

- Excellent free air area of 6%

Soffit Panels

- Manufactured from 26 or 29 ga. Prepainted Steel

- Prepainted Steel, Aluminum, Copper, Stainless Steel and Zinc

- Custom lengths up to 3.1 m

- Precut to required length – no field cutting

- Attractive appearance

- Easy installation – secure with screws or nails to underside of overhang

Applications

- Non-vented: To cover underside of building overhang (soffit)

- Vented: To allow outside air to enter the building and create cross-ventilation

- Venting available in round or slotted holes

- Use in conjunction with roof ventilators

Case Studies & Project Profiles

Welcome to Agway’s ongoing collection of short, inspirational, real-life case histories, published to showcase some of our customers’ more imaginative and effective solutions, both traditional and innovative. This series of project reviews is a celebration of their creative talents in planning, developing and building unique, noteworthy and wonderful structures of all kinds, using quality Agway products, in both the ICI and residential marketplaces. We hope they inspire you to explore your own creative ideas in your next project. Please return to this page often, as we will continue to update this compilation with more new case studies to inspire you and your future creations. It’s just one more tool that makes Agway easier to do business with!