Tuff Board

Features

- High Density Polypropylene Sheet laminated to 3/8″ or 1/2″ plywood

- Government-Accepted for Food Production areas (#3100-3E/144 & #3100-3L/126)

- Strong

- Durable top quality plastic and laminate

- Excellent light reflection

- Will not rust or mildew

- Easy to clean – pressure wash

- Bright smooth ultra-white finish

- Easy to install

- Complete line of accessories available

Resources

Applications

Interior Linings where exposed to dampness and pressure washing, Refrigerated Coolers, Retail or Dairy Operations

Storage Sizes

48” x 8’. Thicknesses:

0.030″ and 0.060″ on 3/8″ plywood

0.060″ on 1/2″ plywood

48″ x 10′ Thickness:

0.040″ on 1/2″ plywood

Storage

Acclimate panels for 24 hrs. prior to installation. This product will expand or contract under certain circumstances.

Installation

Pre-drill holes 1/8” larger than screws. Maximum support spacing is 16” o/c. Maximum fastener spacing along the edge of the sheet is 8” (allowing a minimum of 1” from edge of sheet). Maximum fastener spacing along the intermediate studs is 12”. When fastening to a solid wall, an approved adhesive will help to ensure flatness. For Tuff Board, adhesive must be approved for wood-to-wood contact.

Accessories

- 3/4” Two-piece Drive Rivet, Nylon

- 1-1/2” Two-piece Drive Rivet, Nylon

- #8 x 1-1/2” White Stainless Type A Robertson – Panhead Screws

- Siliconized Interior Acrylic Latex Sealant

3/8” Sheets – 8’ or 12’

1/2” Sheets – 8’

Measurement Type

Poly-Tuff HD Polyethylene Sheet

Agway’s Poly-Tuff High Density Polyethylene Sheets are Government – Accepted for Food Production areas. They are ideal for interior lining, partitions, pens and stalls, equipment & trailer liners, wash bays, horse barns and kennels, arenas, restaurants and applications where moisture or chemicals limit the life of wood.

Resources

Features

- High Density Polyethylene Sheet

- Government-Accepted for Food Production areas (#31003-L121)

- Clean bright smooth white finish

- Easy to clean – pressure wash

- Long life span – extremely hard

- Made from 100% recycled new plastic

- Easy to install – cuts like wood using regular hand tools

- Will not rust or corrode

- Resists attack by most solvents and not affected by petroleum products

- Will not harbour disease or bacteria

Applications

Interior Lining, Partitions, Pens and Stalls, Equipment & Trailer Liners, Wash Bays, Horse Barns and Kennels, Arenas, Restaurants, and applications where moisture or chemicals limit the life of wood.

Storage Sizes

48” x 8’ in 1/8”, 1/4” and 1/2” thicknesses.

Storage

Acclimate panels for 24 hrs. prior to installation. This product will expand or contract under certain circumstances.

Installation

Pre-drill holes 1/8” larger than screws. Panels must be positioned to leave a minimum gap of 1/4” at floor and ceiling and 1/8” between panels. If moldings are being used, these dimensions must be increased proportionally to allow for expansion and contraction. When fastening to a solid wall, an approved adhesive will help to ensure flatness. For Poly-Tuff, adhesive must be approved for Polyethylene sheets.

Accessories

- 3/4” Two-piece Drive Rivet; Nylon

- 1-1/2” Two-piece Drive Rivet; Nylon

- #12 x 3/4” White Stainless Robertson Screws – Pan Head Truss Socket

- #8 x 1-1/2” White Stainless Robertson Screws – Type A Pan Head, no washer

- Interior Acrylic Latex Sealant

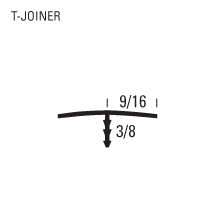

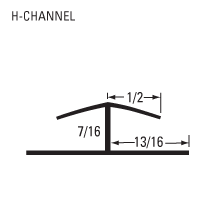

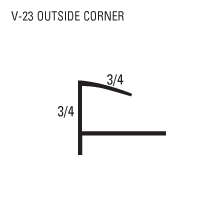

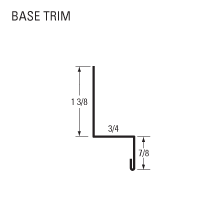

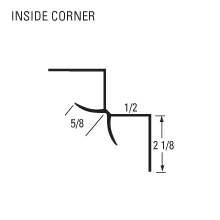

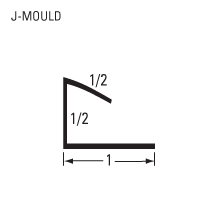

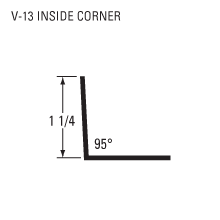

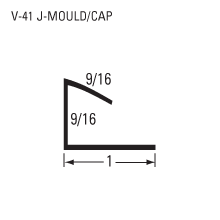

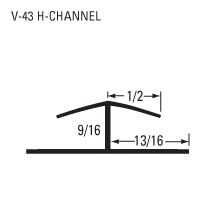

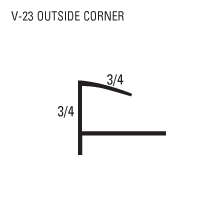

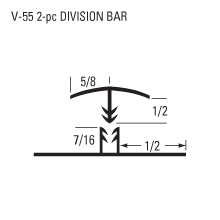

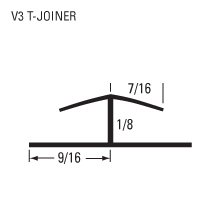

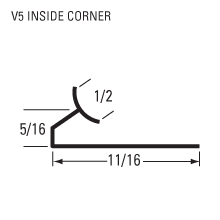

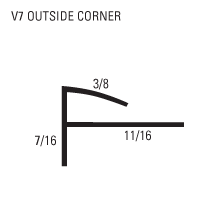

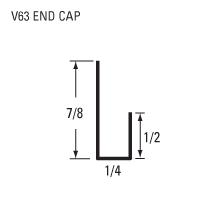

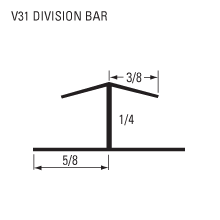

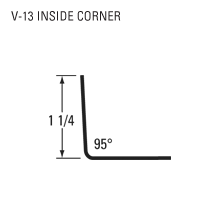

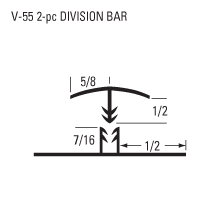

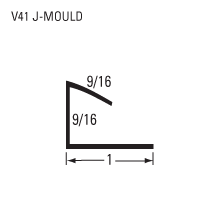

All Trims in 10’ lengths

Trims for 1/8” Sheet

Trims for 1/4” Sheet

Trims for 1/2” Sheet

Measurement Type

Polycarbonate Clear Ridge Cover

Resources

Features

- Clear Polycarbonate UV Resistant Ridge Cover

- Cuts out 98% of UV light

- 10 Year Limited Warranty on yellowing or loss of light transmission

- Up to 90% light transmission

- 20 times the impact resistance of fiberglass of equal thickness with a low temperature extreme of -40°C (-40°F)

- Resists breaking or cracking due to hail, wind and accidental impact

- Provides soft, diffused natural light for farm and industrial buildings

- An ideal way to supplement artificial lighting

Applications

Ridge Closure for use with any configuration of metal roofing when used with the correct closure strip

Storage Sizes

23 1/4” wide x 10’ lengths.

Material Thickness: 1.25 mm (0.050”)

Measurement Type

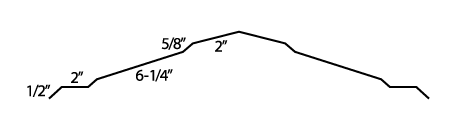

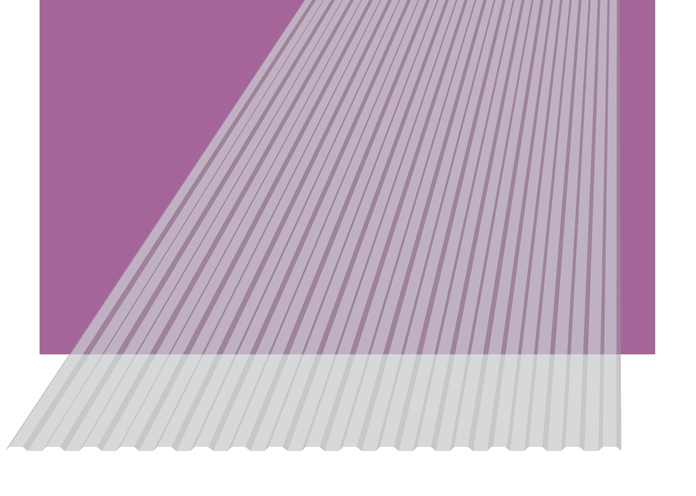

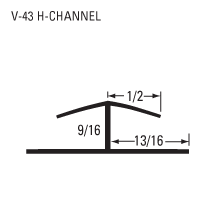

Profiled Polycarbonate Panels

Resources

Features

- Polycarbonate UV Resistant Panel, in Clear or Solar Grey

- 10 Year Limited Warranty on yellowing or loss of light transmission

- 20 times the impact resistance of fiberglass of equal thickness

- Resists breaking or cracking due to hail, wind and accidental impact

- Condensation control allows water to form a thin sheet rather than droplets

Applications

Agricultural Growing Areas, Seeding Frames, Skylights, Riding Arenas and requirements for “Glass-like” uses

Storage Sizes

Clear: 50” x 8’, 12’, 16’. Coverage: 48”.

Material Thickness: 0.79 mm (0.031”)

Solar Grey: 50” x 12’. Coverage: 48”.

Material Thickness: 0.79 mm (0.031”)

Storage

Panels must be stored flat and out of rain or sun

Installation

Pre-drill holes 1/8” larger than screws. Fasten on 24” centres on wood structure. Can be curved; please ask for details. Minimum roof pitch: 3/12

Accessories

- 36” Foam Closures

Measurement Type

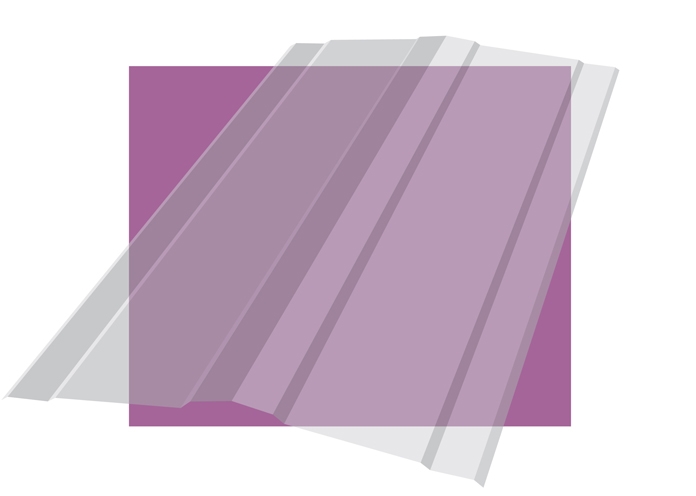

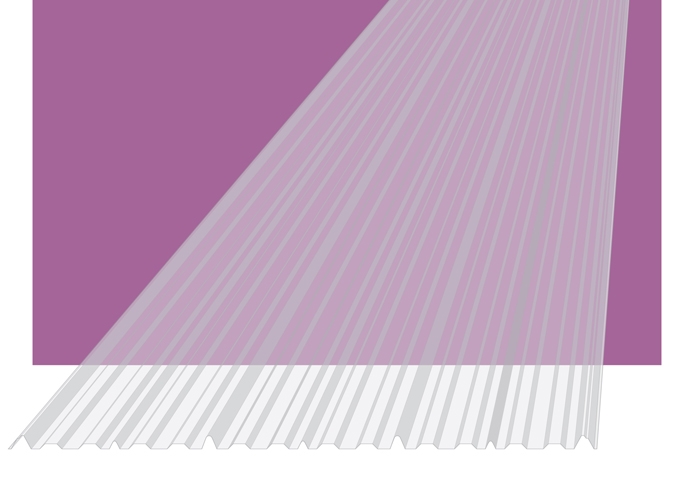

Polycarbonate Century Rib Panels

Agway has two Polycarbonate Panels to choose from. The Polycarbonate Century Rib panel and the Profiled Polycarbonate Panel. Both are ideal for Agricultural growing areas, seeding frames, skylights, riding arenas basically any requirement for “glass-like” uses. A Polycarbonate Clear Ridge Cover that has the capability of eliminating 98% UV light is also an option.

Resources

Features

- Polycarbonate UV Resistant Panel

- 10 Year Limited Warranty on yellowing or loss of light transmission

- Up to 90% light transmission

- 20 times the impact resistance of fiberglass of equal thickness

- Resists breaking or cracking due to hail, wind and accidental impact

Applications

Agricultural Growing Areas, Seeding Frames, Skylights, Riding Arenas and requirements for “Glass-like” uses

Storage Sizes

Sheet: 38” x 12’ with Coverage of 36”.

Thickness: 0.8 mm (0.032”)

Storage

Acclimate panels for 24 hrs. prior to installation.

Panels must be stored flat and out of rain or sun.

Installation

Pre-drill holes 1/8” larger than screws. Fasten on 24” centres on wood structure. Maintain a minimum roof pitch of 3/12. Bends to gentle curves.

Accessories

- Large Tab Century Foam Closures c/w tape

Measurement Type

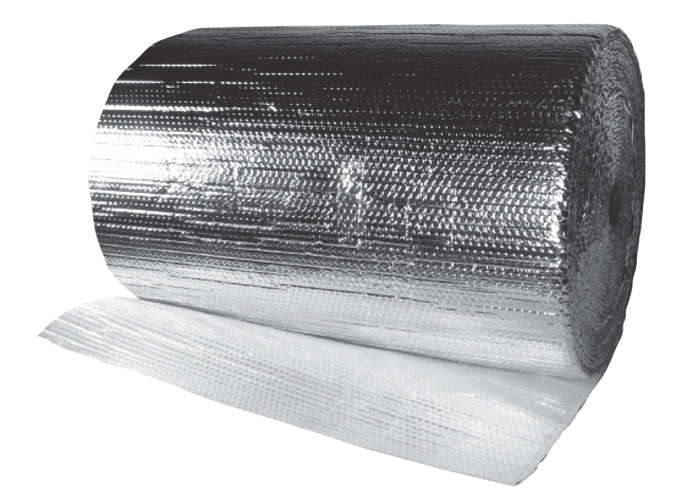

Reflective Insulation

Agway offers two unique styles of Reflective Insulation. Metal Building Reflective Insulation designed to control heat gain or loss, and to prevent interior condensation in all types of metal and metal clad buildings and Concrete Underpad Poly Barrier Foil Insulation designed to provide exceptional thermal value and a strong, permanent Vapour and Radon Barrier.

Resources

Metal Building Reflective Insulation

Product:

- Series 2520 Double Bubble Foil Insulation

- rFOILTM Reflective Insulation is a Double Bubble layer of Polyethylene bubbles bonded to and sandwiched between a radiant barrier metalized foil and white polyethylene sheet

- rFOILTM is specifically designed to control heat gain or loss, and to prevent interior condensation in all types of metal and metal-clad buildings

- rFOILTM meets ASTM E84-09 Fire Test Class 1 / Class A testing

- Square edge, tab 1 side, tab 2 sides, QuickSeam adhesive strip

- Thickness: 5/16” (double)

- Available sizes:

- 6’ x 125’

- 8’ x 125’

Features:

- Reflective metalized aluminum surface facing – lowers heating/cooling costs

- Blocks 97% of radiant heat transfer

- Multi-layer bubble core – does not retain moisture or mould, superior puncture resistance

- White interior facing option – easy to clean, safe, non-toxic and non-carcinogenic

- Practical Tab/Edge options – improves vapour-sealing efforts, UV-resistant

- QuickSeam (adhesive tape on tab) – various tab options ensure continuous vapour and condensation barrier

Applications:

- Pre-engineered steel buildings, post frame / pole barns, agricultural buildings, residential metal roofs, mini-storage units and livestock confinement

Notes:

- Cannot be used under concrete

- Install with white side facing down

Specifications:

| SPECIFICATIONS | DOUBLE | SINGLE |

|---|---|---|

| Nominal Thickness | 5/16″ | 3/16″ |

| Weight | 0.78 oz/ft² | 0.47 oz/ft² |

| Temperature Range (ASTM C411) | -50°F to 180°F | (-45°C to 82°C) |

| Flame Spread (ASTM E84-05) | 5 | 5 |

| Smoke Development (ASTM E84-05) | 5 | 5 |

| Fire Rating (ASTM E84-05) | Class 1 | Class 1 |

| Emissivity (ASTM C1371) 0.03 – 0.04 | 0.03 – 0.04 | |

| Reflectivity (ASTM 3903) 0.96 – 0.97 | 0.96 – 0.97 | |

| Water Vapour Permeance <0.01 Perms | <0.01 Perms | |

| (ASTM E96, ONGC 51.33-M89) | ||

| Tensile & Elongation (ASTM D882) | Maching 69 lbs/sq. in (173%) | |

| Tensile & Elongation (ASTM D882) | Transverse 75 lbs/sq. | |

| Linear Shrinkage | None | |

| Flexibility – CAN/CGSB-51.33 M89 | No Cracking | |

| Resistance to Fungi & Bacteria | Does not promote growth | |

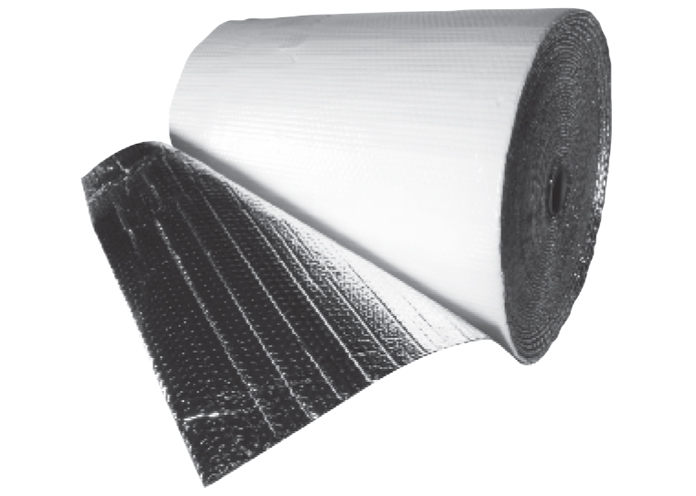

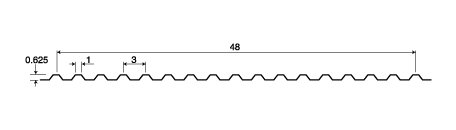

Concrete Underpad Poly Barrier Foil Insulation

Product:

- Series 4320 Double Bubble Concrete Foil Insulation with clear poly on reverse side

- rFOILTM Concrete Underpad is an outstanding Reflective Insulation and puncture-resistant Vapour Barrier

- rFOILTM meets ASTM E84-09 Fire Test Class 1 / Class A testing.

- rFOILTM Concrete Underpad provides exceptional thermal value and a strong, permanent Vapour and Radon Barrier (7 mil)

- Square edge, tab 1 side, tab 2 sides, Quick Seam adhesive strip

- Thickness: 5/16” (double)

- Available sizes:

- 6’ x 125’

- White Poly Tape, 2” x 150’ Roll

Features:

- Reflective metalized aluminum facing (installed face down) – redirects radiant heat energy back to living area and provides a faster reaction time for Radiant Floor heating

- Multi-layer 7 mil bubble core – provides a continuous Thermal Break below the slab, strong puncture resistance and tear strength. Outstanding Vapour and Radon Barrier will also insulate the edge-slab and outside of foundation

- Lightweight flexible materials – just unroll, overlap and tape the seams.

- Ideal for edge-slab insulation and expansion joints;

- Easily folds up at perimeter footing

Applications:

- Insulating under concrete slabs, beneath concrete over-pours, edge-slabs and expansion joints

- Install with clear Poly side facing up

Measurement Type

Agri Plus Insulation

Agway’s AGRI Plus Insulation is a Blanket Insulation that comes with a Vapour Barrier. It features an R Value = 7.0. Ideal for livestock confinement areas, riding arenas workshops, storage sheds and pack barns. It brightens an interior due to high light reflectance.

Resources

Blanket Insulation c/w Vapour Barrier

Features

- R Value = 7.0

- A fibred flexible blanket of insulation faced with a white reinforced vapour barrier

- Controls condensation

- Permanent cost-effective thermal performance; keeps building warm in winter, cool in summer

- Brightens interiors due to high light reflectance

- Effective vapour retarder

- Economical and easy to install in new or existing buildings

- Ideal for livestock confinement areas, riding areans, workshops, storage sheds, pack barns

Thickness

- 2” Thick x 48” Wide x Custom Length

- 2” Thick x 48” Wide x 22’ Roll

- 2” Thick x 48” Wide x 50’ Roll

- Other thicknesses available. (Allow 1-2 weeks for delivery)

Orders From Stock

22′ or 50′ Rolls

Custom Order

Any length, Minimum 5,000 sq.ft. (Allow 7 business days for delivery)

Installation

- Roll out insulation as evenly as possible. Allow 2’ extra for Roof rolls and 1’ extra for walls.

- Pull down to smooth out facing and temporarily secure in place (vice-grips, clamps, etc.)

- Butt rolls closely together and fasten tabs per instructions.

- Pull tabs back through and staple with plier stapler (Arrow P-22 or equal) every 6”. Fold tab over and staple between each original staple.

- Fasten metal sheet according to manufacturer’s instructions.

Measurement Type

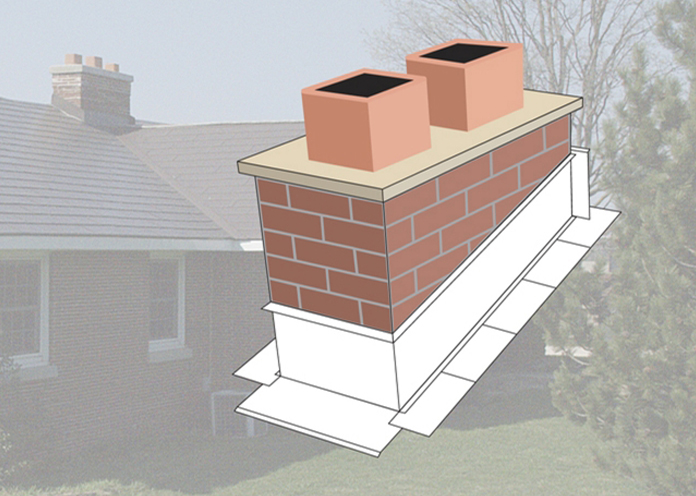

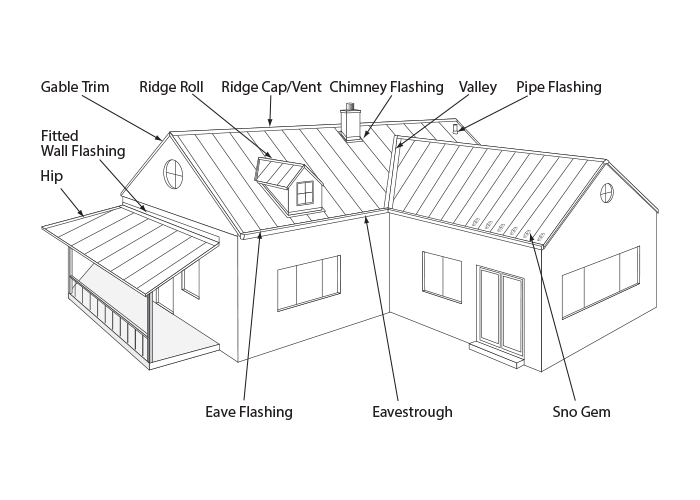

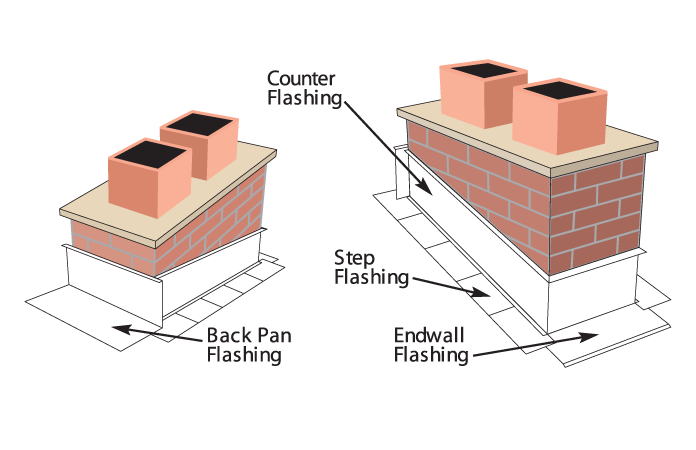

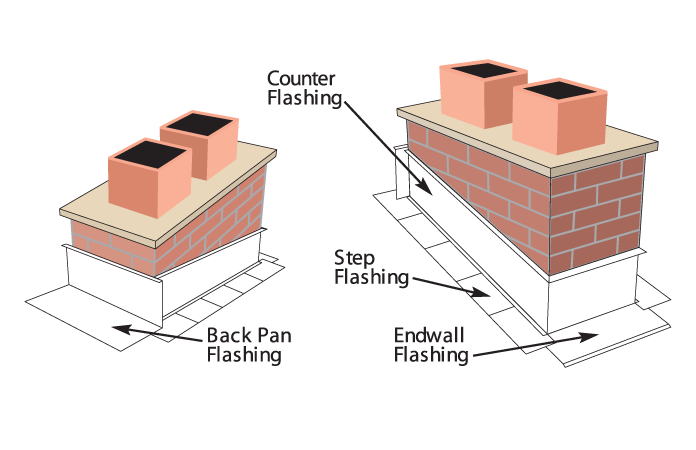

Chimney Flashings

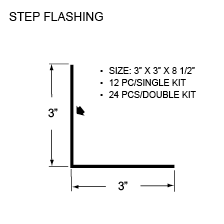

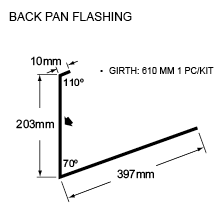

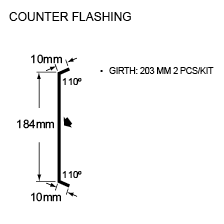

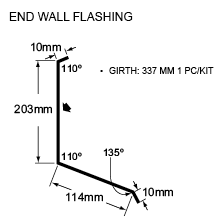

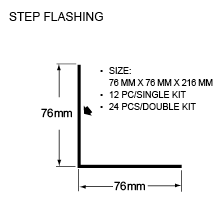

Agway Chimney Kits are available in two sizes – 24” (610 mm) for single chimney and 44” (1118 mm) for double – in four standard colours, including Black, Charcoal, Coffee and Dark Brown (custom colours are also available, but will require wait times). Agway flashings include: Back Pan Flashing; Counter Flashing; End Wall Flashing and Step Flashing, and all are in 29 gauge. Kits come complete with detailed installation instructions.

Measurement Type

Profile Picture

Install Diagram

Chimney Kits are available in two sizes:

- 28” Single Chimney

- 44” Double Chimney (shown)

Stock Colours

- QC18262 Black

- QC18306 Charcoal

- QC18326 Coffee

- QC18229 Dark Brown

* Other colours available – allow 2-3 weeks

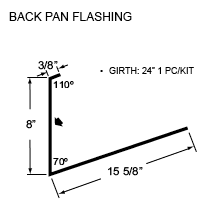

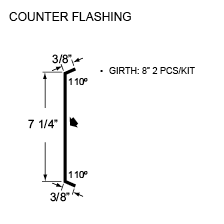

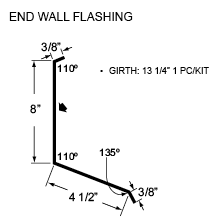

Flashings

Note: All flashings in 29 ga.

Chimney Kit Installation

Note: For Re-Roof applications, strip and clean around existing chimneys make any required repairs to the substrate and chimney.

- Install ice and water protector around the chimney, starting at the bottom and proceeding up the sides, finishing at the top. The top should have a minimum of 24” up the roof and 4” up the chimney; the sides and bottom having 8” on the roof and 4” up the chimney.

- Install the shingle to fit around the chimney; the sealing line should be within 3” of the chimney.

- Install the End Wall Flashing, trim and notch the flashing to extend past the chimney on the roof, and bend the sides up the chimney. Fasten to the roof. Apply a quality butyl sealant at each corner up the roof a minimum of 8″.

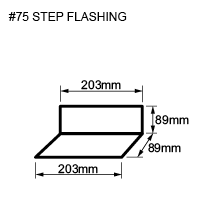

- Start the Step Flashing over the End Wall Flashing and apply a quality butyl sealant on each edge of the step flashing. Continue with each StepFlashing up the sides, finishing at the top by trimming and bending around the top.

- Install the Back Pan Flashing at the top of the chimney and extend beyond the sides of the chimney by at least 3”.

- Install the Counter Flashing on the sides over the Step Flashing. Trim the Counter Flashing to butt to the Back Pan Flashing and over the End Wall Flashing. Fasten into the chimney at 12” centres down the sides and fasten at the front of the End Wall Flashing using waterproof fasteners.

- Apply a quality butyl sealant into the bird’s mouth portion of the Back Pan, Counter and End Wall Flashings. Also apply sealant to the Counter Flashing where it butts against the Back Pan on the vertical seam.

Install Diagram

Chimney Kits are available in two sizes:

- 711 mm Single Chimney

- 1118 mm Double Chimney (shown)

Stock Colours

- QC18262 Black

- QC18306 Charcoal

- QC18326 Coffee

- QC18229 Dark Brown

* Other colours available – allow 2-3 weeks

Flashings

Note: All flashings in 29 ga.

Chimney Kit Installation

Note: For Re-Roof applications, strip and clean around existing chimneys make any required repairs to the substrate and chimney.

- Install ice and water protector around the chimney, starting at the bottom and proceeding up the sides, finishing at the top. The top should have a minimum of 610 mm up the roof and 102 mm up the chimney; the sides and bottom having 203 mm on the roof and 102 mm up the chimney.

- Install the shingle to fit around the chimney; the sealing line should be within 76 mm of the chimney.

- Install the End Wall Flashing, trim and notch the flashing to extend past the chimney on the roof, and bend the sides up the chimney. Fasten to the roof. Apply a quality butyl sealant at each corner up the roof a minimum of 203 mm.

- Start the Step Flashing over the End Wall Flashing and apply a quality butyl sealant on each edge of the step flashing. Continue with each StepFlashing up the sides, finishing at the top by trimming and bending around the top.

- Install the Back Pan Flashing at the top of the chimney and extend beyond the sides of the chimney by at least 76 mm.

- Install the Counter Flashing on the sides over the Step Flashing. Trim the Counter Flashing to butt to the Back Pan Flashing and over the End Wall Flashing. Fasten into the chimney at 305 mm centres down the sides and fasten at the front of the End Wall Flashing using waterproof fasteners.

- Apply a quality butyl sealant into the bird’s mouth portion of the Back Pan, Counter and End Wall Flashings. Also apply sealant to the Counter Flashing where it butts against the Back Pan on the vertical seam.

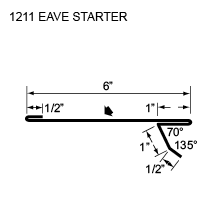

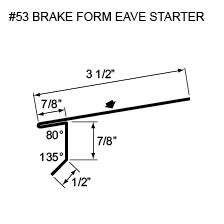

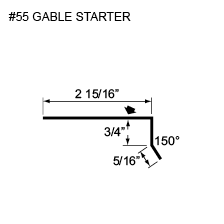

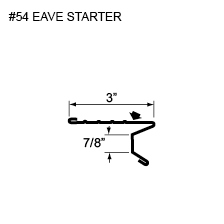

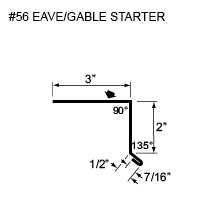

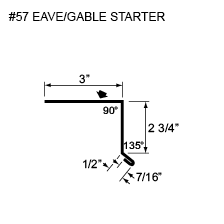

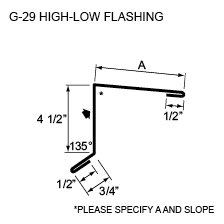

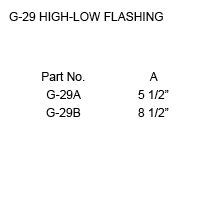

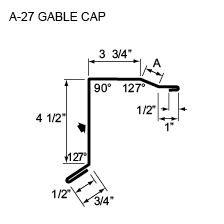

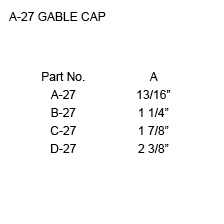

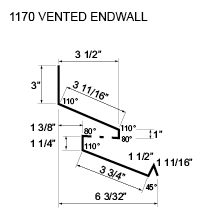

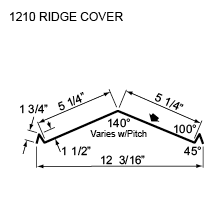

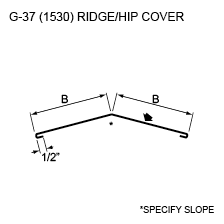

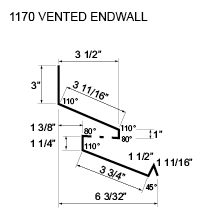

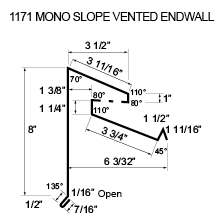

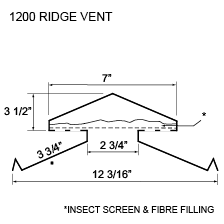

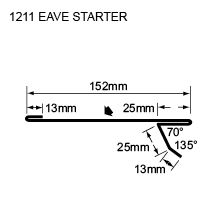

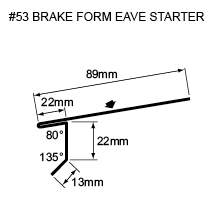

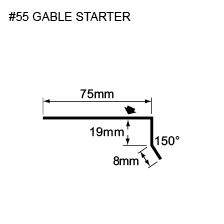

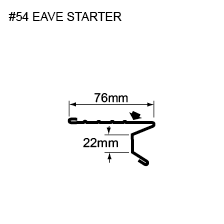

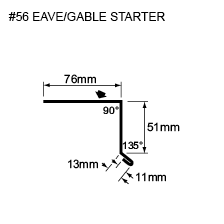

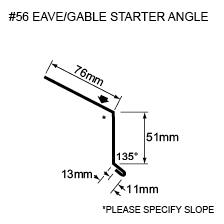

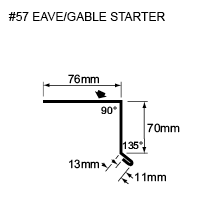

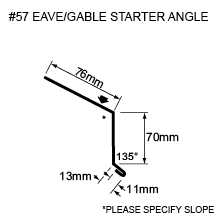

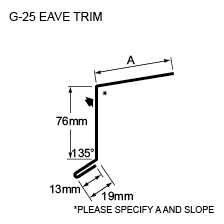

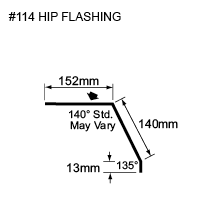

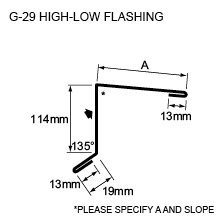

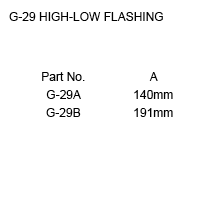

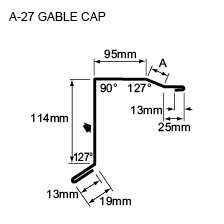

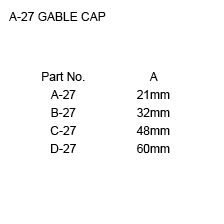

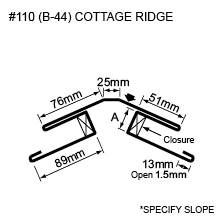

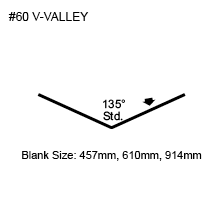

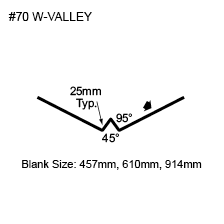

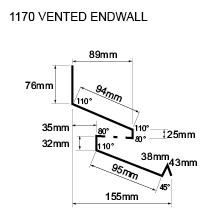

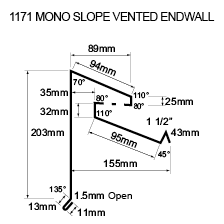

Standard Flashings RES

Agway has everything needed to make it easy to install a new long-lasting, great-looking residential roof. In addition to our celebrated metal roof systems, we offer a complete line of standard flashings and trims to finish off the great looks of your new roof. Our standard metal trims are 10’ – 0” long, but are also available up to 20’ – 0”(some exceptions apply); as well, custom flashings which are available on request. Our standard line includes flashings to conceal exposed fasteners as well as Eave/Gable Starters, Endwalls & Valleys, Vents, Ridges and Snow Stops.

Measurement Type

Profile Picture

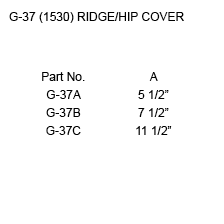

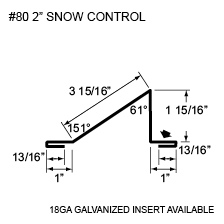

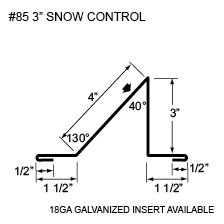

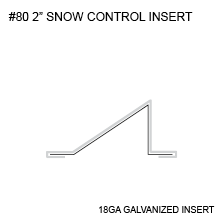

PROFILE LIST

Typical Flashings

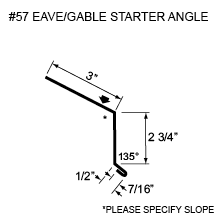

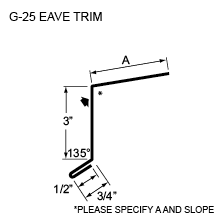

EAVE AND GABLE STARTERS

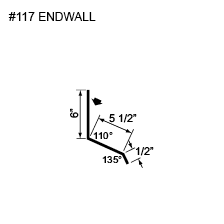

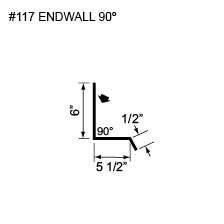

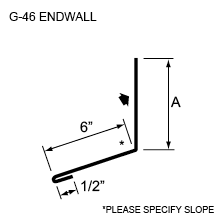

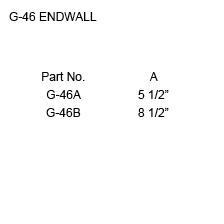

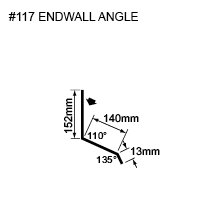

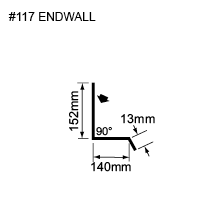

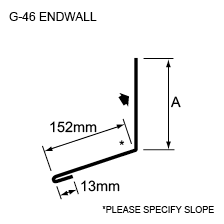

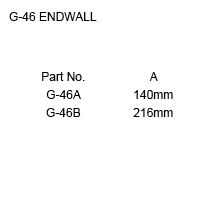

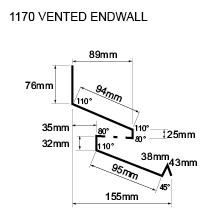

ENDWALLS

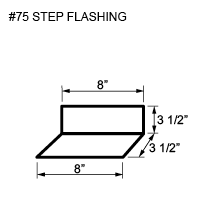

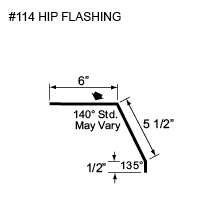

OTHER FLASHINGS

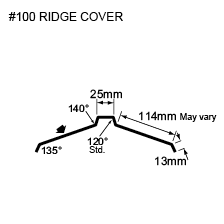

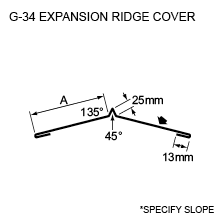

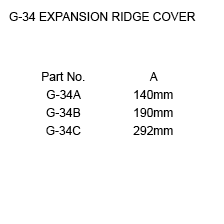

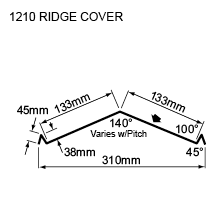

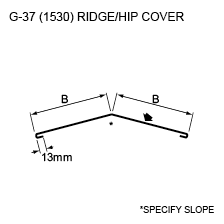

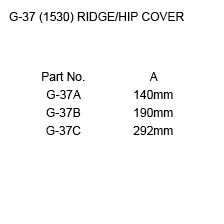

RIDGES

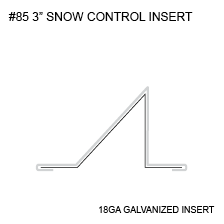

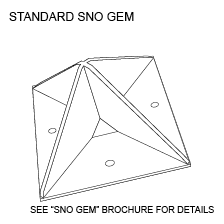

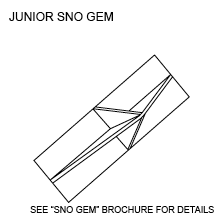

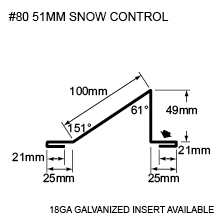

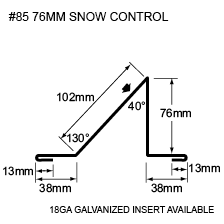

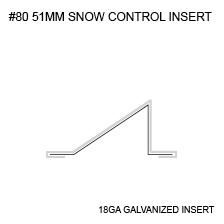

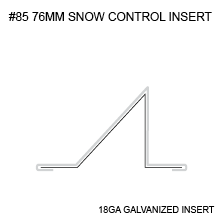

SNOW CONTROL

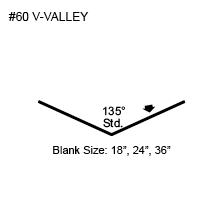

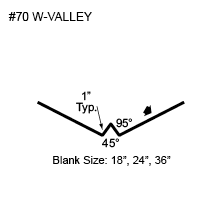

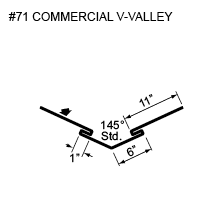

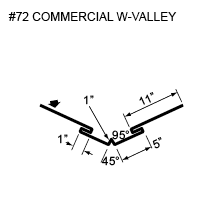

VALLEYS

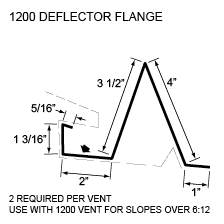

RIDGE VENTS

PROFILE LIST

Typical Flashings

EAVE AND GABLE STARTERS

ENDWALLS

OTHER FLASHINGS

RIDGES

SNOW CONTROL

VALLEYS

RIDGE VENTS

Springhouse Steel Shingles

The Strength and durability of Steel is now available in a shingle style roof. Integrating uncompromised style and design elegance with superior engineering, quality and durability, SPRINGHOUSE SHINGLES™ offer all the benefits of metal roofing in a shingle profile. In addition to faithfully replicating the appearance of traditional shingled roofs, these shingles come with the guaranteed peace of mind that the new roof will last a lifetime. So, over that lifetime of the roof, SPRINGHOUSE SHINGLES eliminate the inconvenience of future roof installations and actually cost less over the full life-time of your home.

A traditional residential roof made with asphalt shingles starts deteriorating the moment it’s installed. Springhouse steel shingles mean you no longer have to choose between appearance and long life. Offering the strength of steel, Springhouse shingles can withstand winds of 120 mph and are impervious to everything nature throws at them, including hail, moisture, extreme weather and temperatures and pollutants. They are also immune to damage from termites, molds and other destructive pests, and able to shed snow, which helps prevent the formation of ice dams and the resulting potential damage. Springhouse steel shingles are, literally, maintenance-free for life.

Springhouse shingles can be installed over an existing roof, thereby reducing waste and environmental pollution, while eliminating the costs of removing and disposing of old shingles. In addition, all the metal in Springhouse shingles is 100% recyclable.

Available in a wide selection of gorgeous colours and finishes, Springhouse steel shingles will elevate the aesthetics of a roof to new heights of beauty, while complementing the home it protects, as well as its natural surroundings. It’s the last roof you’ll install on your home.

Resources

Measurement Type

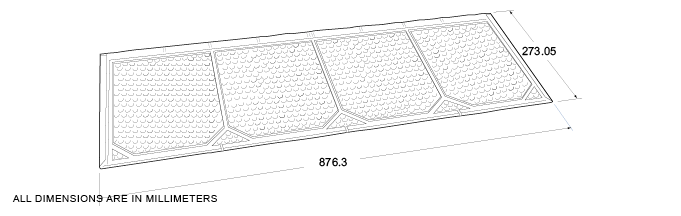

Profile Picture

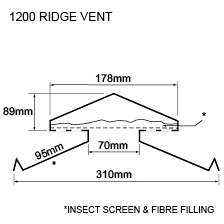

Dimensions & Specifications

- Maintenance free

- KYNAR 500 Paint System

- Granite Deep Mat colour system

- Can be applied over existing asphalt shingles

- Walkable – you can walk on this material without causing damage

- 8 standard colours, other colours / finishes available upon request

- Textured finish

- No exposed cut edges

- Concealed fasteners

- Long life span

- Transferable Warranty

Panel Specifications

| MIN/MAX SLOPE |

MIN/MAX MATERIAL THICKNESS |

MIN/MAX SHEET LENGTH |

SHINGLE SIZE |

|---|---|---|---|

| 3/12 – 12/12 | 0.015 in | 10 3/4” x 34 1/2” |

Dimensions & Specifications

- Maintenance free

- KYNAR 500 Paint System

- Granite Deep Mat colour system

- Can be applied over existing asphalt shingles

- Walkable – you can walk on this material without causing damage

- 8 standard colours, other colours / finishes available upon request

- Textured finish

- No exposed cut edges

- Concealed fasteners

- Long life span

- Transferable Warranty

Panel Specifications

| MIN/MAX SLOPE |

MIN/MAX MATERIAL THICKNESS |

MIN/MAX SHEET LENGTH |

SHINGLE SIZE |

|---|---|---|---|

| 3/12 – 12/12 | 0.381 mm | 27 cm x 88 cm |

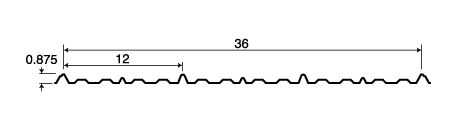

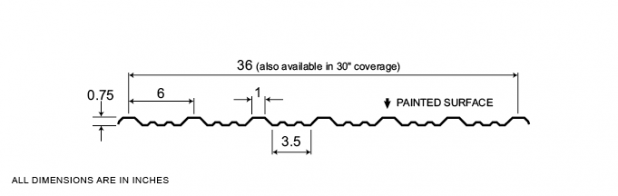

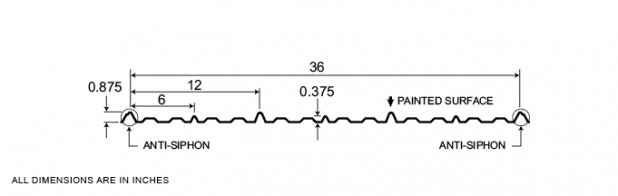

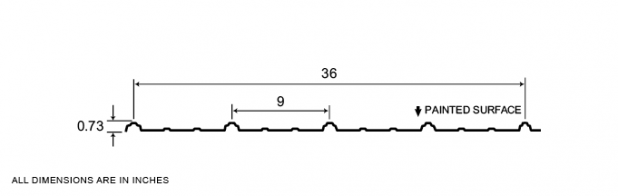

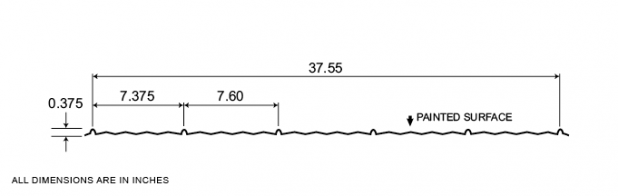

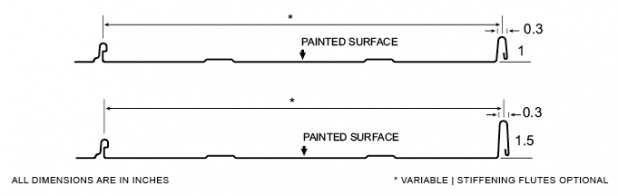

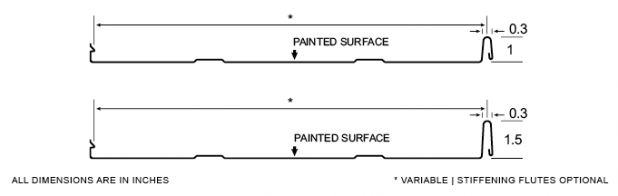

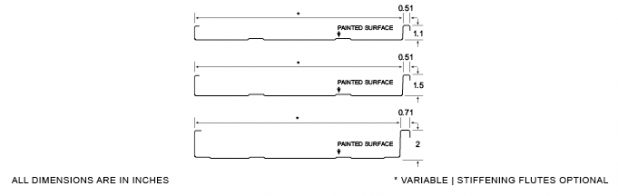

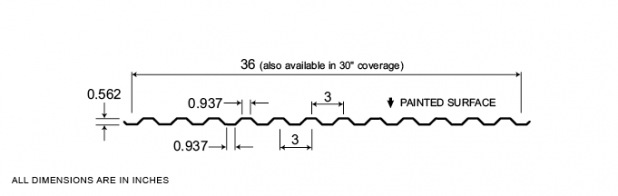

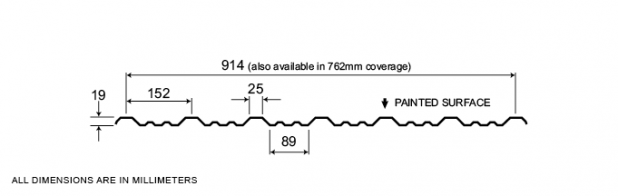

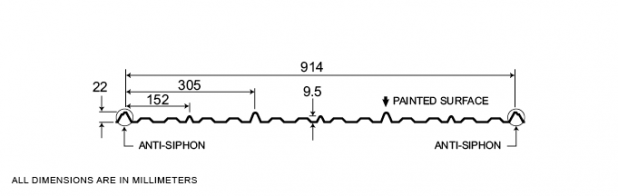

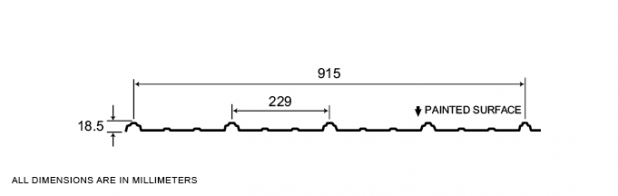

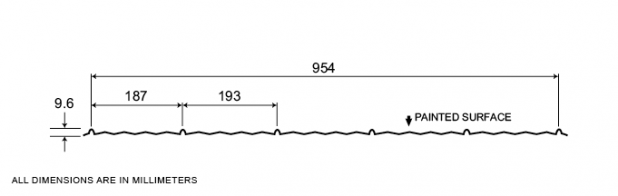

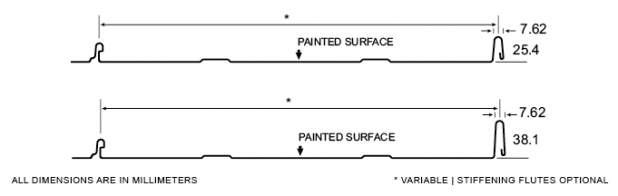

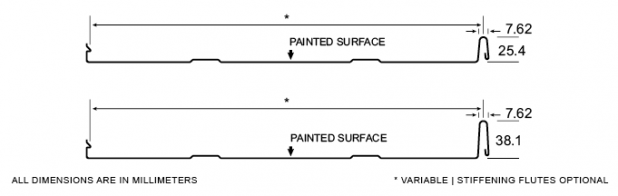

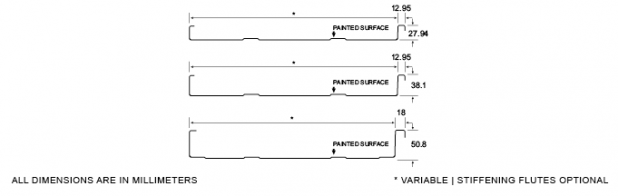

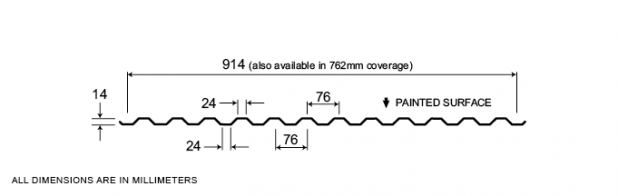

Lo-Rib

Among the most economical panels on the market, Agway’s lightweight Lo-rib profile is ideal for use on high sloped roofs, or as exterior and interior siding. Lo-Rib installs easily and adds a professional finish to any structure. Available in a wide range of colours, Agway’s Lo Rib profile, combined with available trims, fasteners and other accessories, provides a complete solution for any project.

Measurement Type

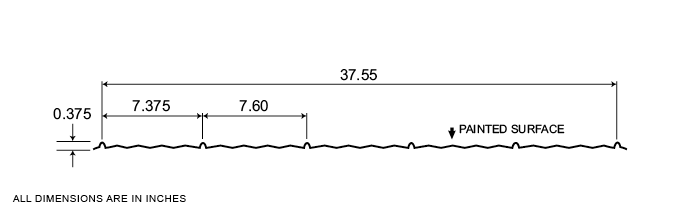

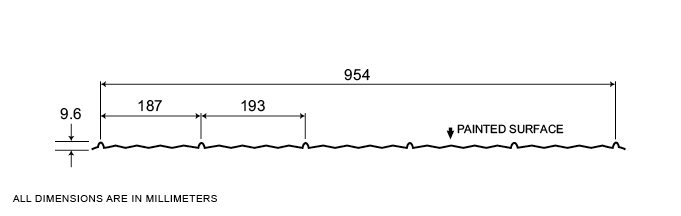

Profile Picture

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 10 | 600 | 37.55 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 254 | 15.24 | 954 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0120 | 0.560 | 80 | |||

| 0.0135 | 0.626 | 80 | |||

| 0.0180 | 0.813 | 50 | |||

| 0.0240 | 1.037 | 33 | |||

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.305 | 2.73 | 550 | |||

| 0.343 | 3.06 | 550 | |||

| 0.457 | 3.97 | 345 | |||

| 0.610 | 5.06 | 230 | |||