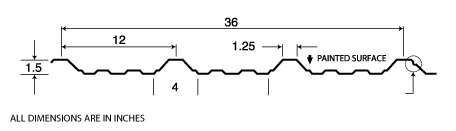

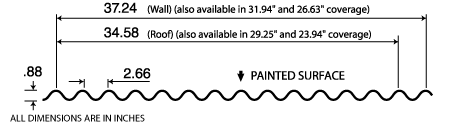

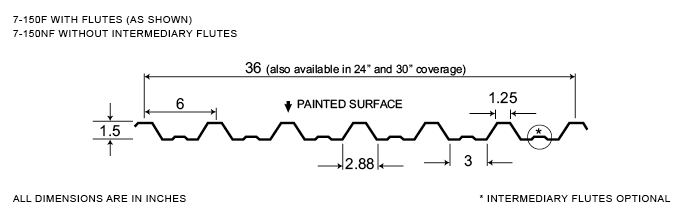

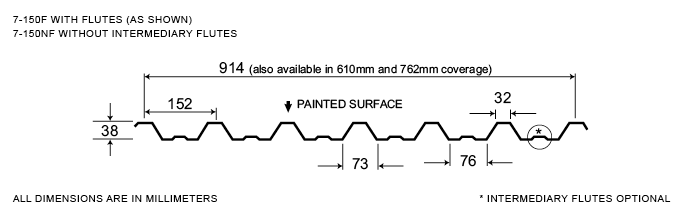

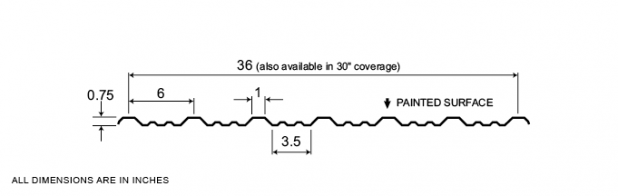

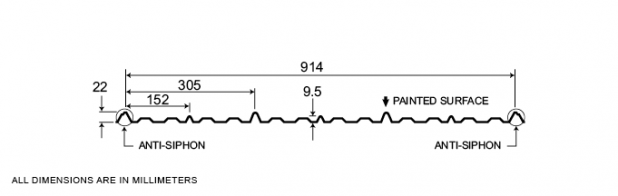

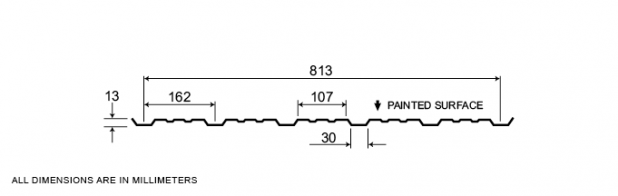

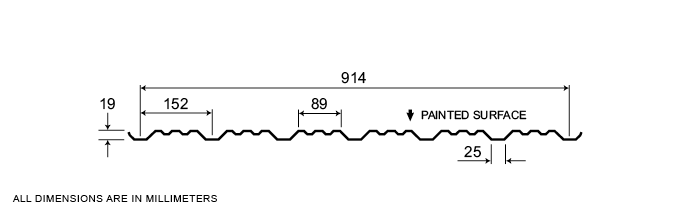

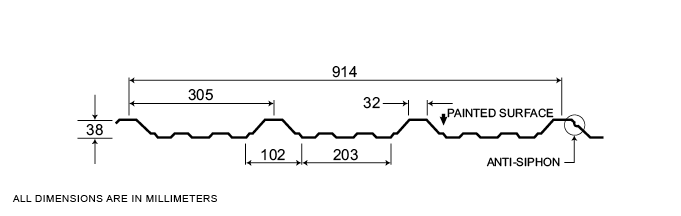

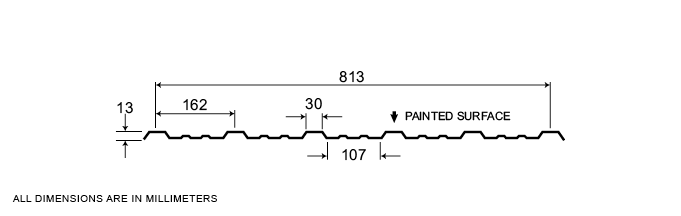

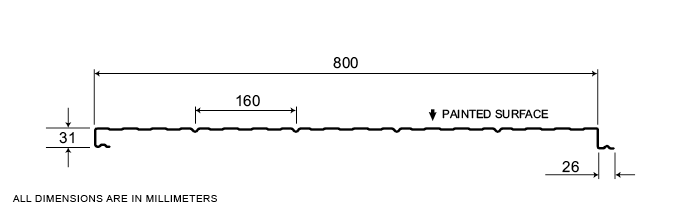

7-150

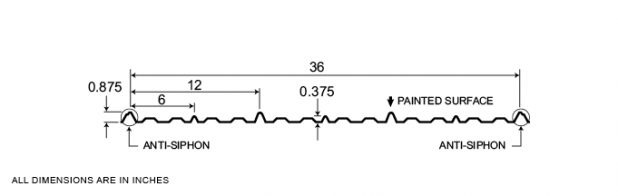

An exposed fastener system, the 7-150 profile demonstrates the versatility of Agway profile designs as it can be used as a roof or wall cladding. Moreover, its load bearing capabilities enable the 7-150 profile to function as a structural member. An economical system that’s easy to install, 7-150 is a popular choice for agricultural, industrial and commercial applications.

Agway’s 7-150 comes in a full range of stock colours, with colour matched fasteners, trims and accessories.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 26 | 20 | 10 | 780 | 36 |

| 26 | 20 | 10 | 780 | 30 |

| 26 | 20 | 10 | 780 | 24 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 26 | 20 | 254 | 19.81 | 914 |

| 26 | 20 | 254 | 19.81 | 780 |

| 26 | 20 | 254 | 19.81 | 610 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.018 | 1.04 | 33 | 0.0940 | 0.0888 | 0.0985 |

| 0.024 | 1.36 | 33 | 0.136 | 0.127 | 0.132 |

| 0.030 | 1.69 | 33 | 0.175 | 0.162 | 0.165 |

| 0.036 | 2.02 | 33 | 0.208 | 0.198 | 0.197 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.457 | 5.06 | 230 | 5.05 | 4.77 | 0.134 |

| 0.610 | 6.66 | 230 | 7.28 | 6.82 | 0.180 |

| 0.762 | 8.25 | 230 | 9.38 | 8.73 | 0.225 |

| 0.914 | 9.85 | 230 | 11.2 | 10.7 | 0.270 |

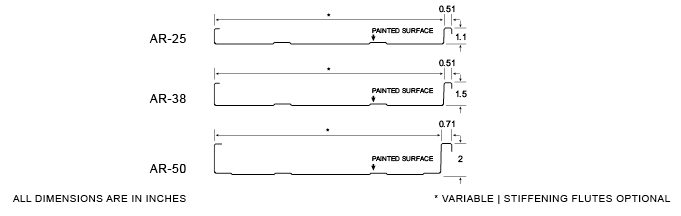

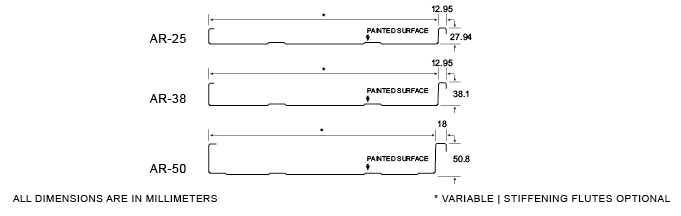

AR Standing Seam

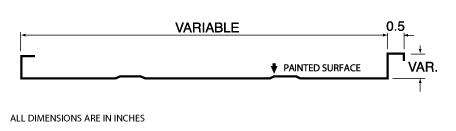

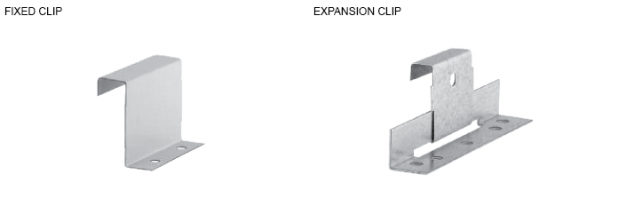

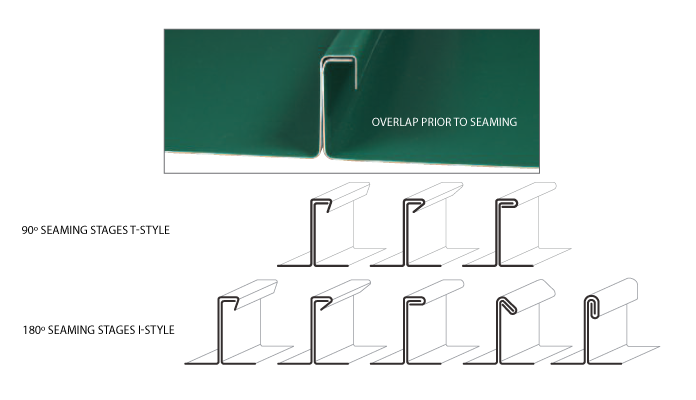

Our Standing Seam AR metal roofing is available in 24 and 22 gauge, in variable widths and with side lap rib heights of 1”, 1 ½” or 2”. Agway’s AR series also features optional, two-piece expansion clips to accommodate movement of the roof, and can be seamed at either 90º or 180º. With a 180º seam and optional seam caulking, panels can be used on low slopes (AR-38 down to 1.5/12 and AR-50 down to 0.5/12).

Unlike many traditional alternatives like slate or tile, our Standing Seam Profile is easy to install, more cost effective, 100% recyclable and facilitates more creativity in design. In fact, this profile can even be curved!

Whether you choose a profile from our Standing Seam, Nail Strip, or Snap Lock roof cladding systems, the result will be a stunning, architecturally distinctive roof that installs easily and has no exposed fasteners. All these durable Agway roof cladding products are available in a full range of stock colours, in variable panel widths, and with optional stiffening flutes. All are single skin applications and must be applied over a solid substrate and waterproof membrane, using clips at a maximum of 2’ centres. A full range of flashings and accessories are available from Agway to complete your project.

Measurement Type

Profile Picture

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| AR-25 | 3/12 – 12/12 | 0.0236” – 0.030” | 2′ 6″ – 45′ | 6″ – 28″ |

| AR-38 | 1.5/12 – 12/12 | 0.0236” – 0.030” | 2′ 6″ – 45′ | 6″ – 28″ |

| AR-50 | 0.5/12 – 12/12 | 0.0236” – 0.030” | 2′ 6″ – 45′ | 8″ – 24.5″ |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For AR-25, AR-38 or AR-50 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 48”

Standard Panel Widths

| GAUGE | AR-25 | AR-38 | AR-50 |

|---|---|---|---|

| 24 | 21.06″ | 20.06″ | 18.52″ |

| 22 | 21.06″ | 20.06″ | 18.52″ |

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Concealed hold-down clips

- Knee Caps available

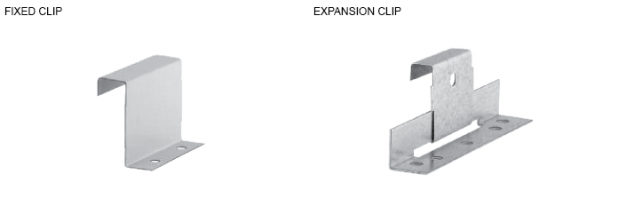

- Optional two-piece expansion clip to accommodate roof movement

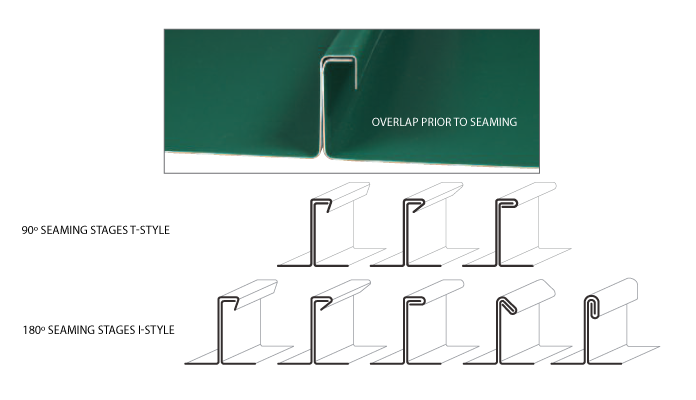

- 24 gauge can be seamed 90° and 180°; 22 gauge can be seamed 90° only

- Butyl Tape is recommended in 90° seams

- Able to be curved – minimum sheet length 5’-0”

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that AR Series profiles be applied over waterproof membrane

- Clips at maximum 2’ centres – 2 fasteners per clip

- Mechanical and Hand Seamer required. For seamer purchase & rental visit the D.I. Roof Seamers website – or by calling D.I. Roof Installers at 1-888-343-0456

Hold-Down Clip Detail

Overlap Seaming Options

Panel Specifications

| MIN/MAX | MIN/MAX | MIN/MAX | MIN/MAX | |

|---|---|---|---|---|

| SLOPE | MATERIAL THICKNESS | SHEET LENGTH | PANEL WIDTH | |

| AR-25 | 3/12 – 12/12 | 0.610 – 0.762 mm | 0.76 – 13.71 m | 152 – 711 mm |

| AR-38 | 1.5/12 – 12/12 | 0.610 – 0.762 mm | 0.76 – 13.71 m | 152 – 711 mm |

| AR-50 | 0.5/12 – 12/12 | 0.610 – 0.762 mm | 0.76 – 13.71 m | 203 – 622 mm |

- Side lap caulking is recommended when the slope is less than 2/12

- Longer sheets are available. Additional charges may apply.

- For AR-25, AR-38 or AR-50 with 180 degree seam – maximum gauge is 24 GA

- Short sheet charge for any lengths under 1,219 mm

Standard Panel Widths

| GAUGE | AR-25 | AR-38 | AR-50 |

|---|---|---|---|

| 24 | 21.06″ (535 mm) |

20.06″ (509.5 mm) |

18.52″ (470 mm) |

| 22 | 21.06″ (535 mm) |

20.06″ (509.5 mm) |

18.52″ (470 mm) |

Features

- No exposed fasteners

- Ease of installation

- Full range of stock colours

- Variable width

- Optional stiffening flutes

- Concealed hold-down clips

- Knee Caps available

- Optional two-piece expansion clip to accommodate roof movement

- 24 gauge can be seamed 90° and 180°; 22 gauge can be seamed 90° only

- Butyl Tape is recommended in 90° seams

- Able to be curved – minimum sheet length: 1.52m

Oil Canning

- Oil Canning is naturally occurring phenomenon inherent in all sheet steel.

- Oil Canning is not a valid reason for rejection of these products

Installation

- Single skin application

- Recommended that this always be applied over solid substrate

- Recommended that AR Series profiles be applied over waterproof membrane

- Clips at maximum 61 cm centers – 2 fasteners per clip

- Mechanical and Hand Seamer required. For seamer purchase & rental visit the D.I. Roof Seamers website – or by calling D.I. Roof Installers at 1-888-343-0456

Hold-Down Clip Detail

Overlap Seaming Options

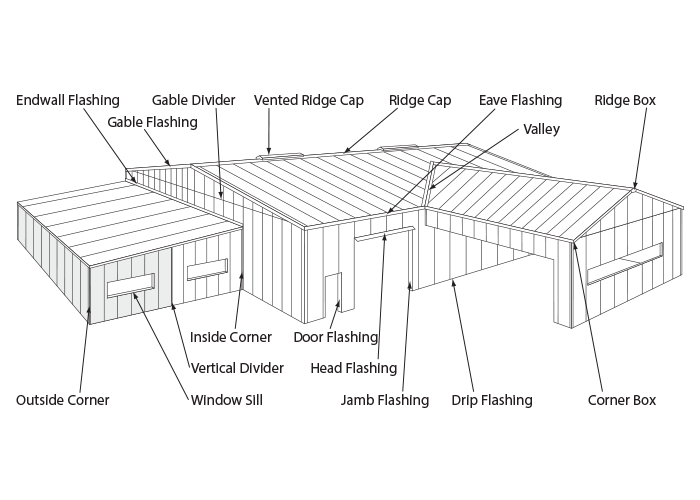

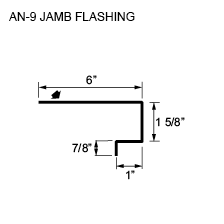

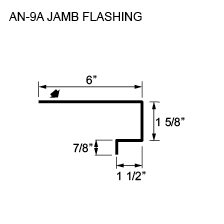

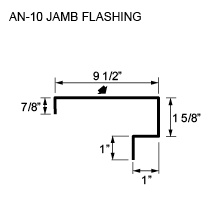

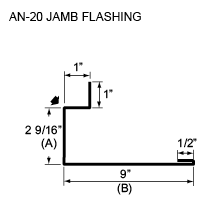

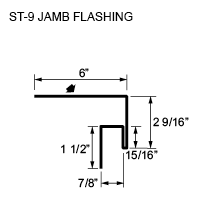

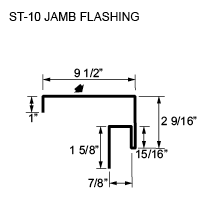

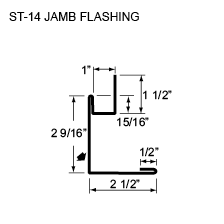

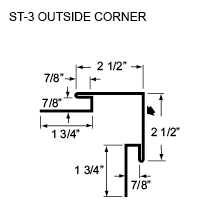

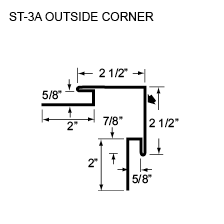

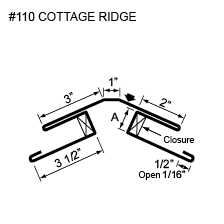

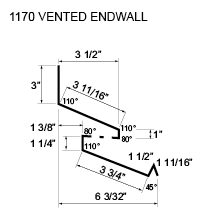

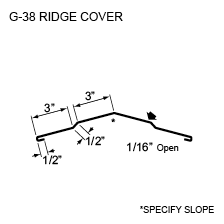

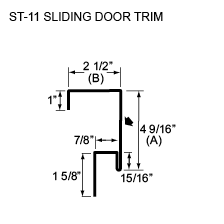

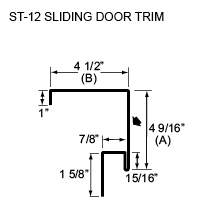

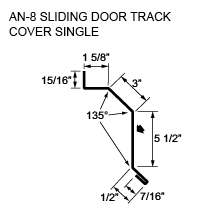

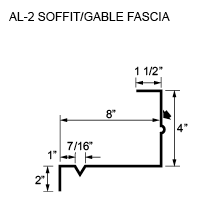

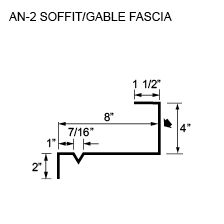

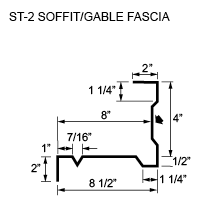

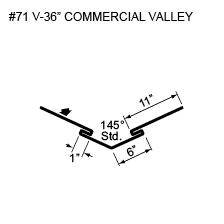

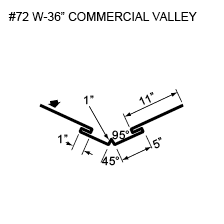

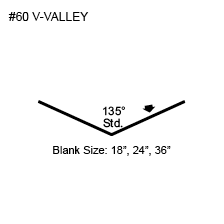

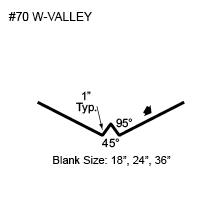

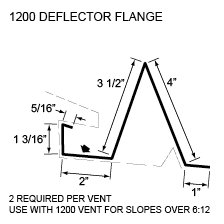

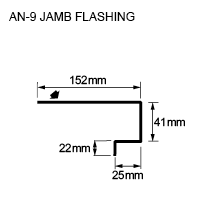

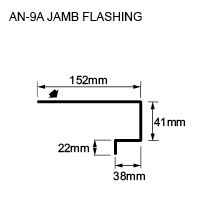

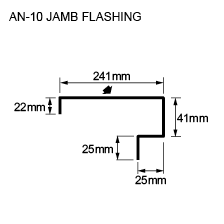

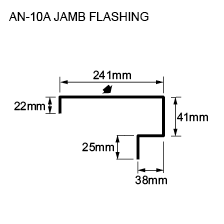

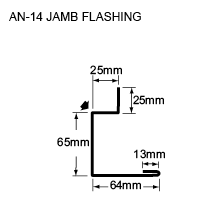

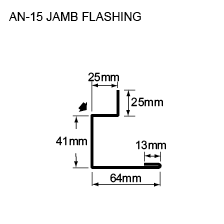

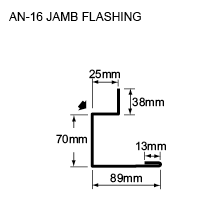

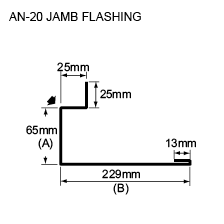

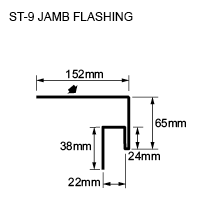

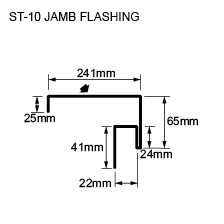

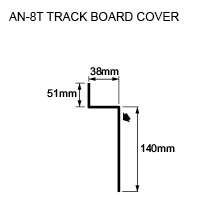

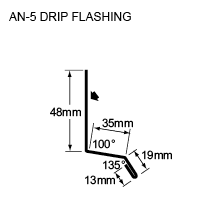

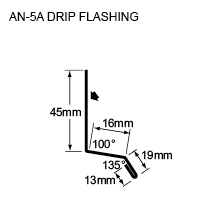

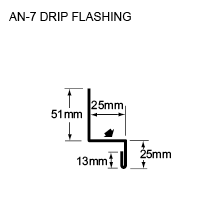

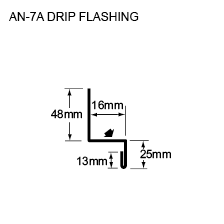

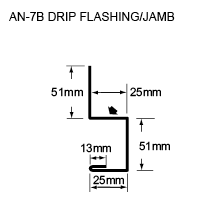

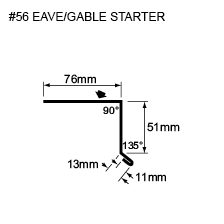

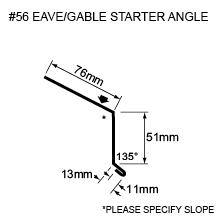

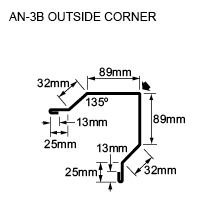

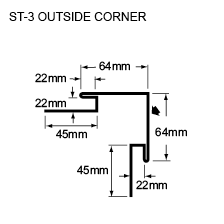

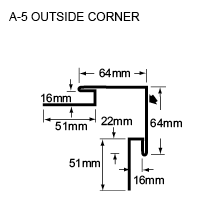

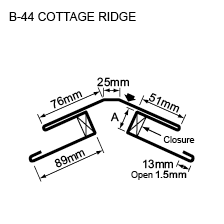

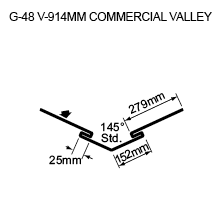

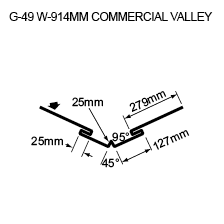

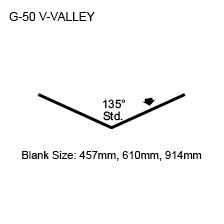

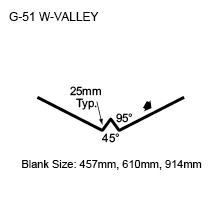

Standard Flashings LWC

At Agway you can find everything required in flashings and trims in order to complete your light gauge cladding requirements. From Outside Corners to Vents, Ridges and Valleys Agway has it all. Trims come in standard 10’ lengths, but can be ordered in lengths up to 20’. Custom flashings are also available on request.

Resources

Measurement Type

Profile Picture

PROFILE LIST

Typical Flashings

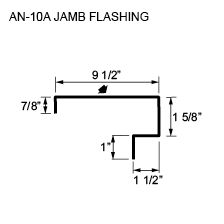

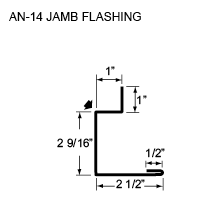

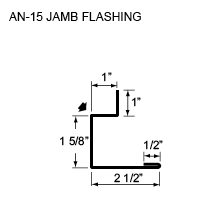

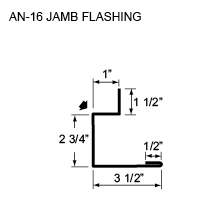

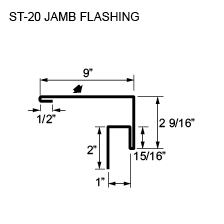

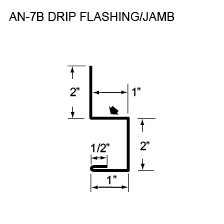

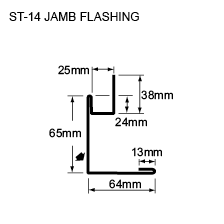

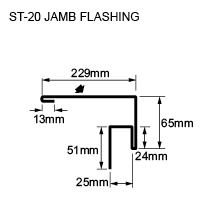

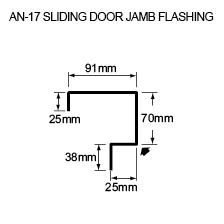

JAMBS

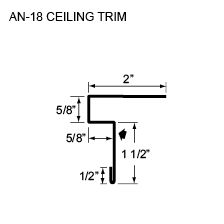

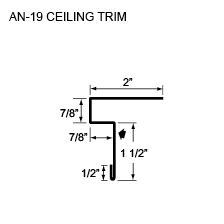

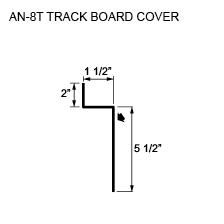

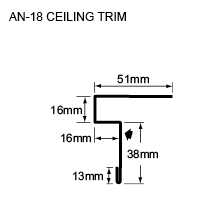

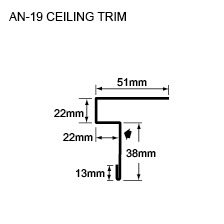

CEILING TRIMS

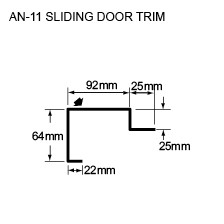

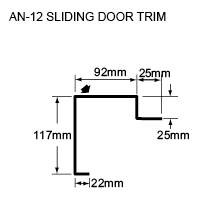

DOOR TRIMS

DRIP AND BASE TRIMS

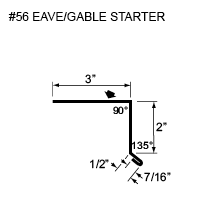

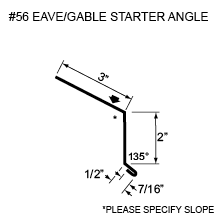

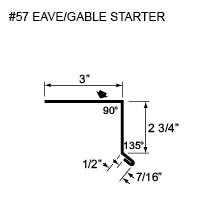

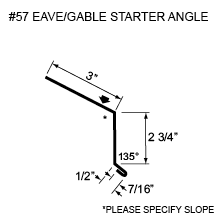

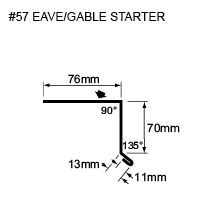

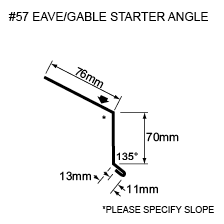

EAVE AND GABLE STARTERS

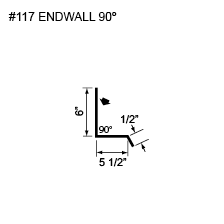

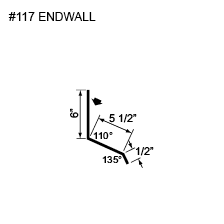

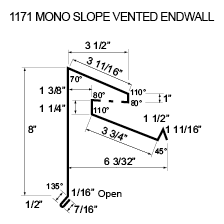

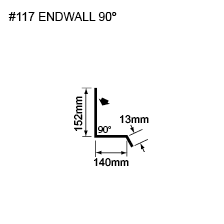

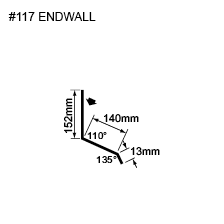

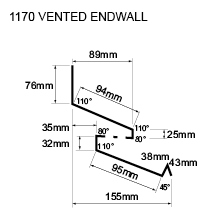

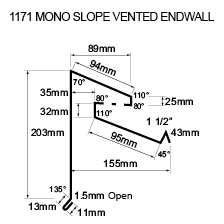

ENDWALLS

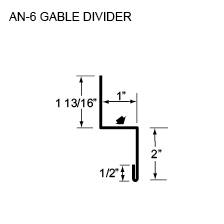

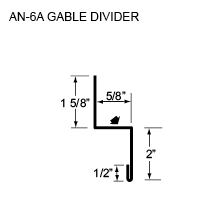

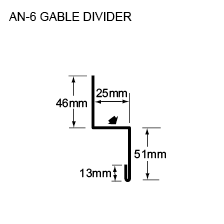

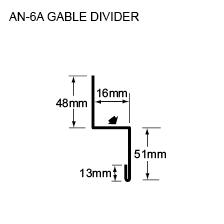

GABLE DIVIDERS

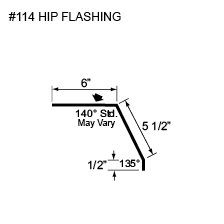

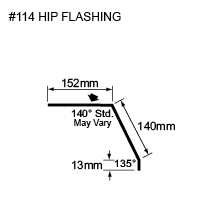

HIP FLASHINGS

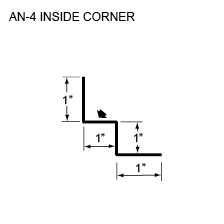

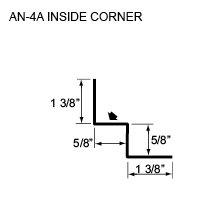

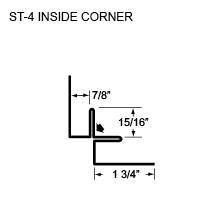

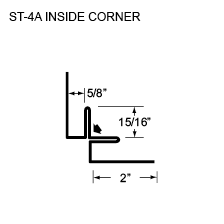

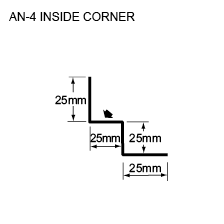

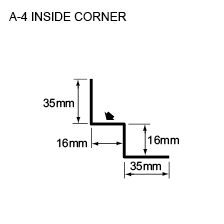

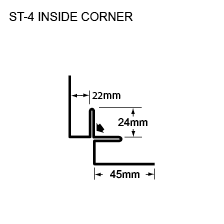

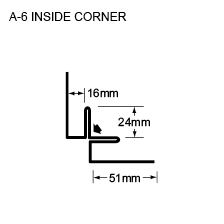

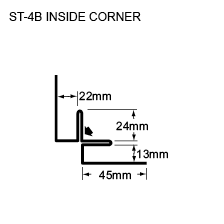

INSIDE CORNERS

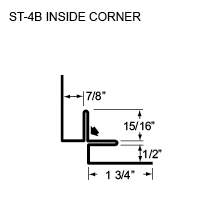

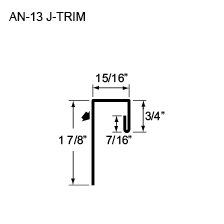

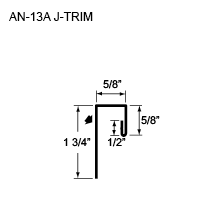

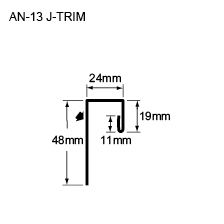

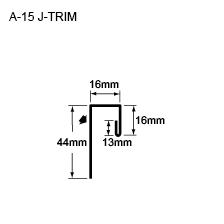

J-TRIMS

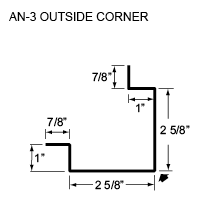

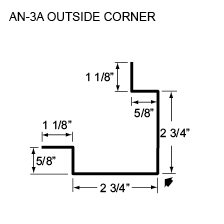

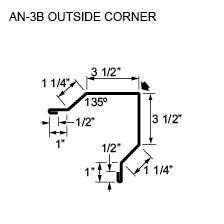

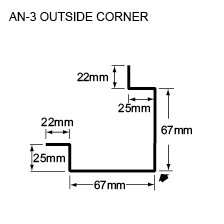

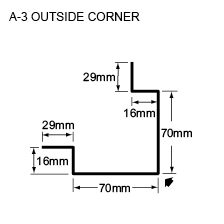

OUTSIDE CORNERS

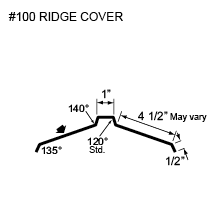

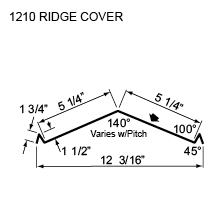

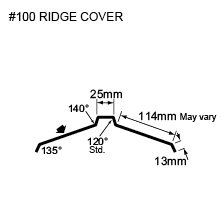

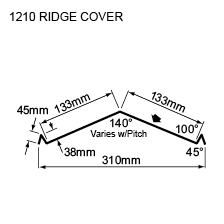

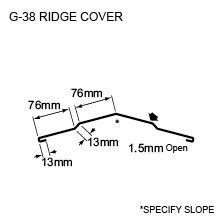

RIDGES

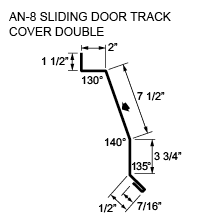

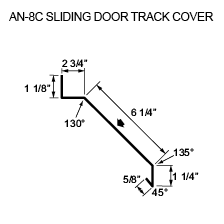

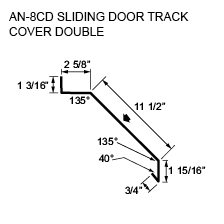

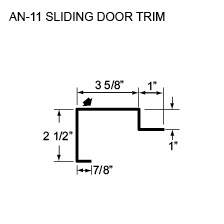

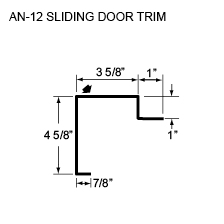

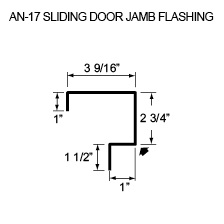

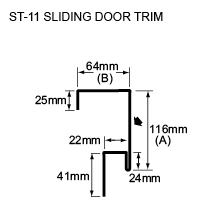

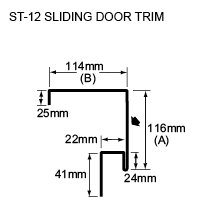

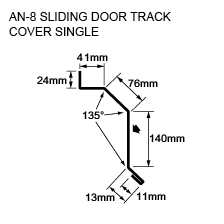

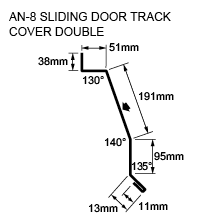

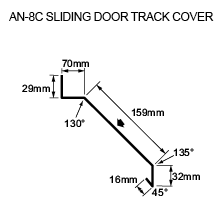

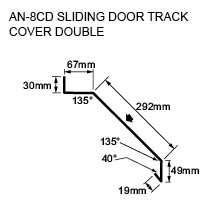

SLIDING DOOR TRIMS

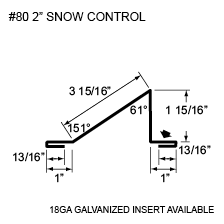

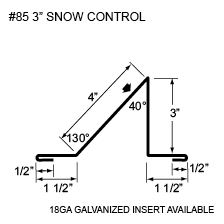

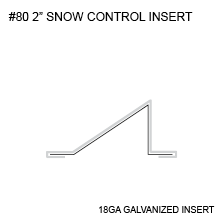

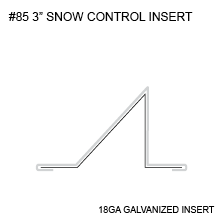

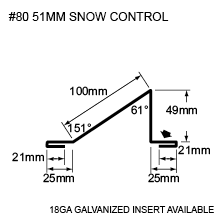

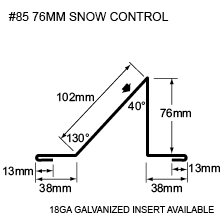

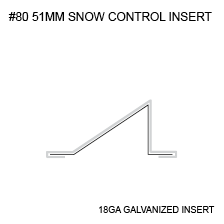

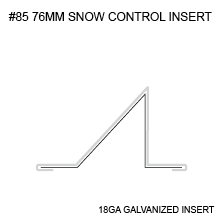

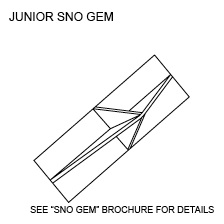

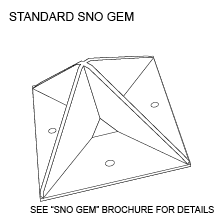

SNOW CONTROL

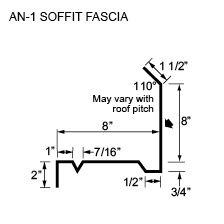

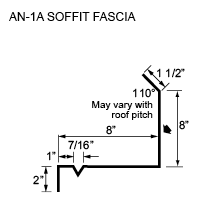

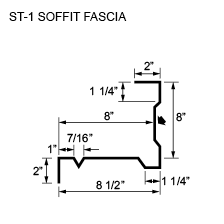

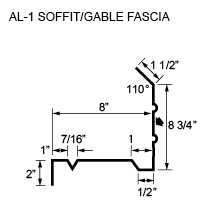

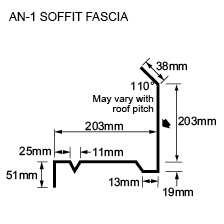

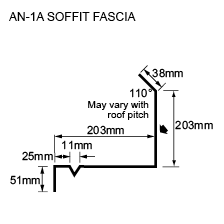

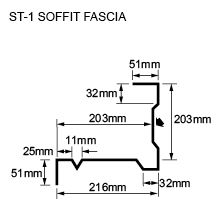

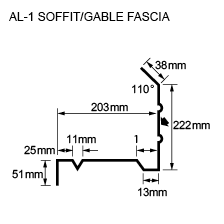

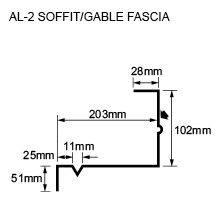

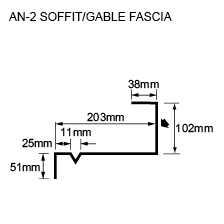

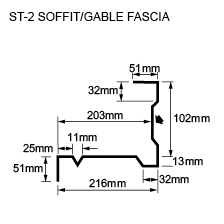

SOFFIT AND GABLE TRIMS

VALLEYS

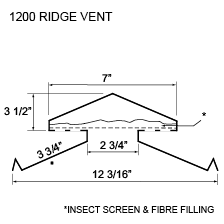

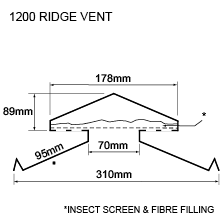

VENTS

PROFILE LIST

Typical Flashings

JAMBS

CEILING TRIMS

DOOR TRIMS

DRIP AND BASE TRIMS

EAVE AND GABLE STARTERS

ENDWALLS

GABLE DIVIDERS

HIP FLASHINGS

INSIDE CORNERS

J-TRIMS

OUTSIDE CORNERS

RIDGES

SLIDING DOOR TRIMS

SNOW CONTROL

SOFFIT AND GABLE TRIMS

VALLEYS

VENTS

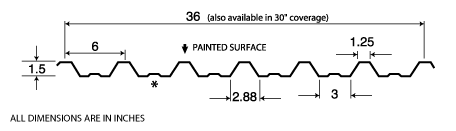

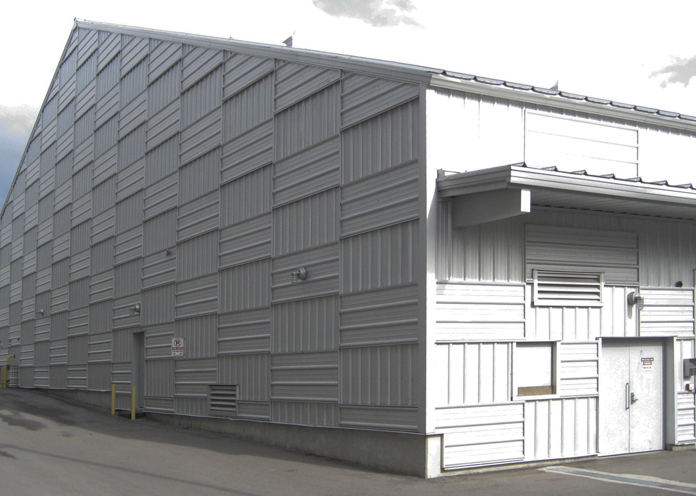

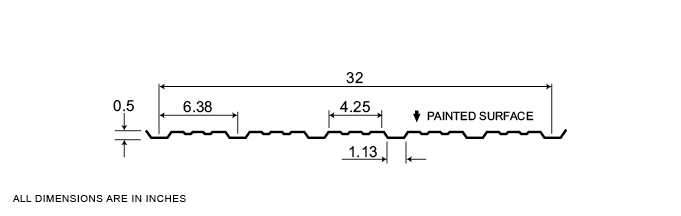

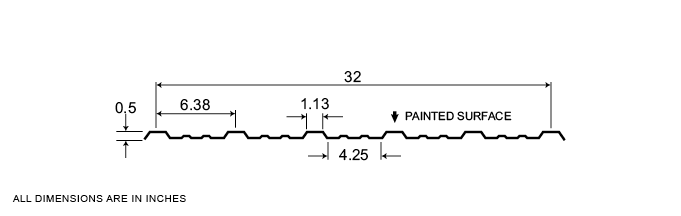

CH5-32

Our economical, easy-to-install, CH5-32 lightweight wall system adds a professionally finished look to the exterior or interior of any structure. For convenience and versatility, these 32” panels can be installed vertically or horizontally and, once installed, are extremely weather resistant and virtually maintenance free. Available in a wide range of colours, Agway’s CH5-32 profile, combined with available trims, fasteners and other accessories, provides a complete solution for any project.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 22 | 10 | 540 | 32 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 22 | 254 | 13.72 | 813 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.012 | 0.61 | 33 | 0.011 | 0.0116 | 0.0037 |

| 0.0150 | 0.68 | 33 | 0.0112 | 0.012 | 0.0039 |

| 0.018 | 0.88 | 33 | 0.0207 | 0.0208 | 0.0072 |

| 0.024 | 1.16 | 33 | 0.0304 | 0.0312 | 0.0107 |

| 0.03 | 1.43 | 33 | 0.0386 | 0.0413 | 0.0144 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.305 | 2.97 | 230 | 0.59 | 0.621 | 0.0051 |

| 0.381 | 3.3 | 230 | 0.6 | 0.643 | 0.0053 |

| 0.457 | 4.31 | 230 | 1.11 | 1.12 | 0.0093 |

| 0.61 | 5.66 | 230 | 1.63 | 1.67 | 0.0146 |

| 0.762 | 7 | 230 | 2.07 | 2.22 | 0.0196 |

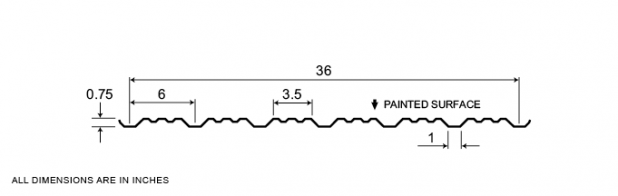

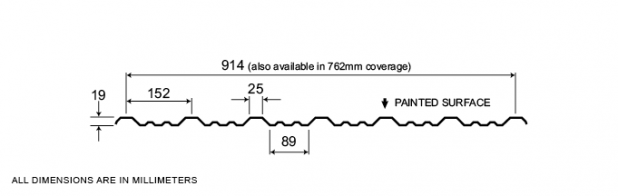

DR6-75

The Agway DR6-75 series features an inverted Diamond Rib profile, which presents a visually ‘softer’ finished look to surfaces. These versatile, lightweight panels are extremely weather resistant and virtually maintenance free. For added flexibility and convenience, panels can be installed vertically or horizontally and are available in a wide range of colours, Agway’s DR6-75 profile, combined with available trims, fasteners and other accessories, provides a complete cladding solution for any project.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 16 | 540 | 36 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 406 | 13.72 | 914 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0120 | 0.64 | 33 | 0.0202 | 0.0221 | 0.0098 |

| 0.0135 | 0.71 | 80 | 0.0208 | 0.0232 | 0.0102 |

| 0.0180 | 0.93 | 33 | 0.0361 | 0.0381 | 0.0182 |

| 0.0240 | 1.22 | 33 | 0.0498 | 0.0550 | 0.0268 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.305 | 3.11 | 230 | 1.09 | 1.19 | 0.0133 |

| 0.343 | 3.46 | 550 | 1.12 | 1.25 | 0.0140 |

| 0.457 | 4.52 | 230 | 1.94 | 2.04 | 0.0248 |

| 0.610 | 5.94 | 230 | 2.68 | 2.96 | 0.0366 |

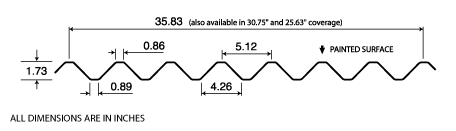

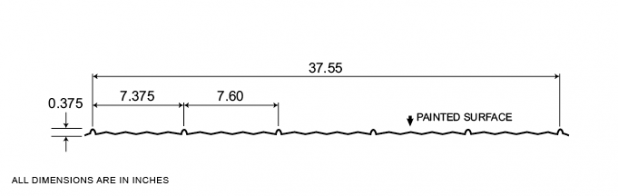

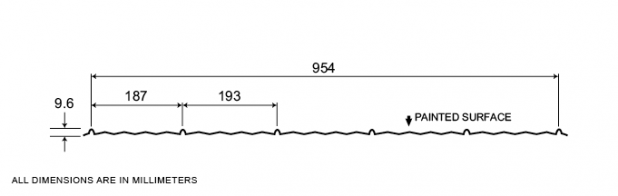

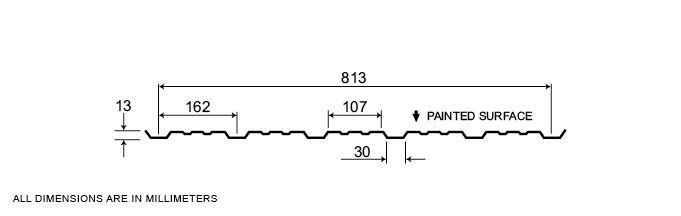

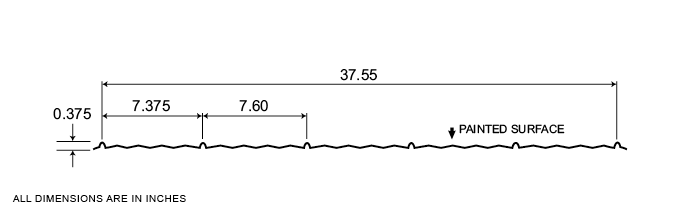

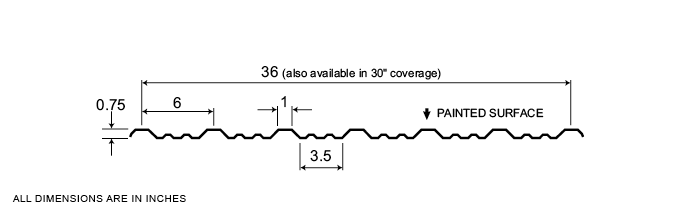

Lo-Rib

Among the most economical panels on the market, Agway’s lightweight Lo-rib profile is ideal for use on high sloped roofs, or as exterior and interior siding. Lo-Rib installs easily and adds a professional finish to any structure. Available in a wide range of colours, Agway’s Lo Rib profile, combined with available trims, fasteners and other accessories, provides a complete solution for any project.

Measurement Type

Profile Picture

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 10 | 600 | 37.55 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 254 | 15.24 | 954 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0120 | 0.560 | 80 | |||

| 0.0135 | 0.626 | 80 | |||

| 0.0180 | 0.813 | 50 | |||

| 0.0240 | 1.037 | 33 | |||

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.305 | 2.73 | 550 | |||

| 0.343 | 3.06 | 550 | |||

| 0.457 | 3.97 | 345 | |||

| 0.610 | 5.06 | 230 | |||

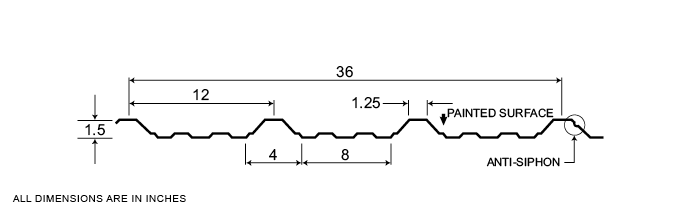

4-150

When a more dramatic exterior appearance or stronger profile is required, Agway’s economical, easy-to-install 4-150 profile is your choice. This versatile profile can be installed as a wall cladding or roof cladding and it’s 1 3/8” rib depth provides extra strength to allow for wider support spacing. Available in a wide range of colours, Agway’s 4-150 profile, combined with available trims, fasteners and other accessories, provides a complete solution for any project.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 29 | 22 | 10 | 828 | 36 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 29 | 22 | 254 | 21.03 | 914 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0135 | 0.73 | 80 | 0.0340 | 0.0278 | 0.0455 |

| 0.0150 | 0.80 | 33 | 0.0428 | 0.0364 | 0.0564 |

| 0.0180 | 0.95 | 50 | 0.0509 | 0.0432 | 0.0673 |

| 0.0240 | 1.25 | 33 | 0.0777 | 0.0674 | 0.0938 |

| 0.0300 | 1.55 | 33 | 0.101 | 0.0867 | 0.117 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.343 | 3.55 | 550 | 1.83 | 1.49 | 0.0621 |

| 0.381 | 3.91 | 230 | 2.30 | 1.95 | 0.0769 |

| 0.457 | 4.64 | 345 | 2.74 | 2.32 | 0.0919 |

| 0.610 | 6.09 | 230 | 4.17 | 3.62 | 0.128 |

| 0.762 | 7.54 | 230 | 5.45 | 4.66 | 0.160 |

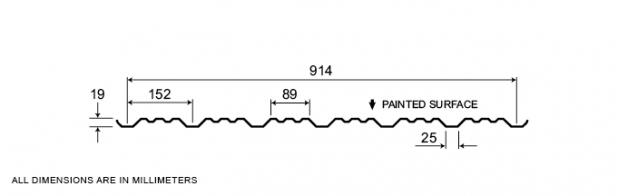

Diamond Rib

Agway’s Diamond Rib profile is one of our most popular and versatile lightweight profiles. Economical and easy to install, the Diamond Rib profile is the standard wall cladding for agricultural applications, and captures the classic barn look. For convenience and simplicity, these versatile panels can be installed vertically or horizontally on a wall, or as a roof panel and, once installed, are extremely weather resistant and virtually maintenance free. Available in a wide range of colours, Agway’s Diamond Rib profile, combined with available trims, vents, fasteners and other accessories, provides a complete cladding solution for any project.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a

deflection limit

of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a

deflection limit

of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 16 | 540 | 36 |

| 30 | 22 | 16 | 480 | 30 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 406 | 13.72 | 914 |

| 30 | 22 | 406 | 12.92 | 780 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0120 | 0.64 | 33 | 0.0221 | 0.0202 | 0.0144 |

| 0.0135 | 0.71 | 80 | 0.0227 | 0.0203 | 0.0152 |

| 0.0180 | 0.93 | 33 | 0.0381 | 0.0361 | 0.0227 |

| 0.0240 | 1.22 | 33 | 0.0550 | 0.0498 | 0.0302 |

| 0.0300 | 1.51 | 33 | 0.0683 | 0.0637 | 0.0637 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.305 | 3.11 | 230 | 1.19 | 1.09 | 0.0196 |

| 0.343 | 3.46 | 550 | 1.22 | 1.09 | 0.0207 |

| 0.457 | 4.52 | 230 | 2.04 | 1.94 | 0.0309 |

| 0.610 | 5.94 | 230 | 2.96 | 2.68 | 0.0412 |

| 0.762 | 7.36 | 230 | 3.67 | 3.42 | 0.0514 |

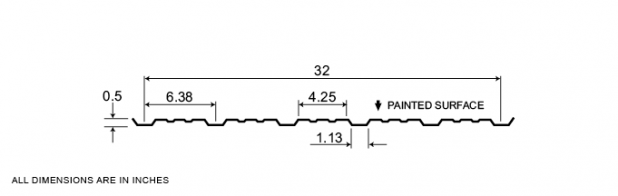

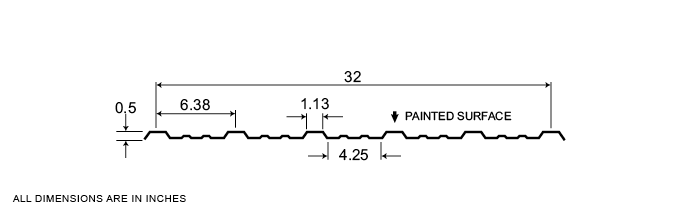

CH6-32

Our economical, easy-to-install, CH6-32 lightweight wall system adds a professionally finished look to the exterior or interior of any structure. For convenience and versatility, these 32” panels can be installed vertically or horizontally and, once installed, are extremely weather resistant and virtually maintenance free. Available in a wide range of colours, Agway’s CH5-32 profile, combined with available trims, fasteners and other accessories, provides a complete solution for any project.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 22 | 10 | 540 | 32 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 22 | 254 | 13.72 | 813 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.012 | 0.61 | 33 | 0.0116 | 0.011 | 0.0056 |

| 0.0150 | 0.68 | 33 | 0.0116 | 0.0108 | 0.0056 |

| 0.018 | 0.88 | 33 | 0.0208 | 0.0207 | 0.0092 |

| 0.024 | 1.16 | 33 | 0.0312 | 0.0304 | 0.0125 |

| 0.03 | 1.43 | 33 | 0.0413 | 0.0386 | 0.0156 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.305 | 2.97 | 230 | 0.621 | 0.59 | 0.0076 |

| 0.381 | 3.3 | 230 | 0.625 | 0.58 | 0.0077 |

| 0.457 | 4.31 | 230 | 1.12 | 1.11 | 0.0126 |

| 0.61 | 5.66 | 230 | 1.67 | 1.63 | 0.0171 |

| 0.762 | 7 | 230 | 2.22 | 2.07 | 0.0213 |

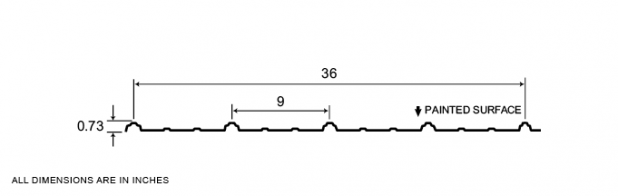

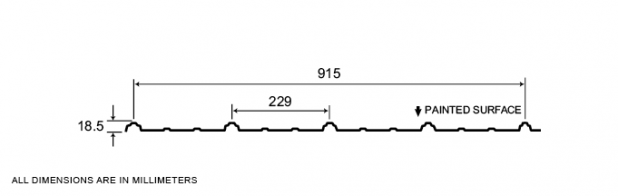

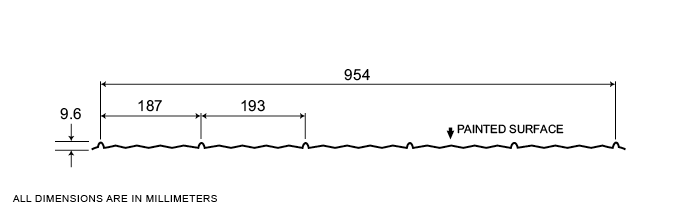

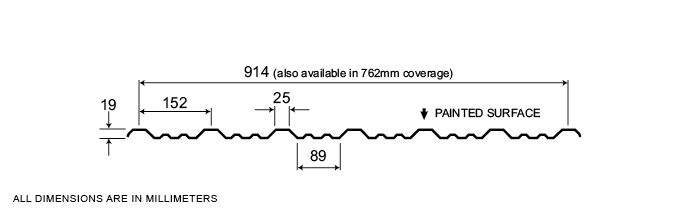

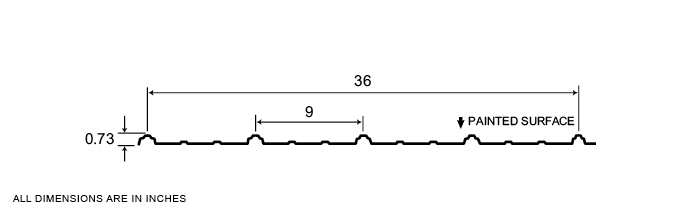

Optimum Rib

A very popular profile for agricultural roof applications, our economical, easy-to-install, Optimum Rib lightweight panels add a professionally finished look to the exterior of any structure. Available in a wide range of colours, Agway’s Optimum Rib profile, combined with available trims, vents, fasteners and other accessories provides a complete cladding solution for any project.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

8. Plain or painted Galvalume sheets should not be used on Animal Confinement Buildings.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 30 | 780 | 36 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 24 | 762 | 19.81 | 915 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

| 0.0135 | 0.71 | 80 | 0.0126 | 0.0099 | 0.0083 |

| 0.0180 | 0.93 | 33 | 0.0167 | 0.0144 | 0.0110 |

| 0.0240 | 1.22 | 33 | 0.0220 | 0.0198 | 0.0146 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

|

|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

| 0.343 | 3.46 | 550 | 0.676 | 0.533 | 0.0113 |

| 0.457 | 4.52 | 230 | 0.895 | 0.772 | 0.0150 |

| 0.610 | 5.94 | 230 | 1.18 | 1.07 | 0.0199 |

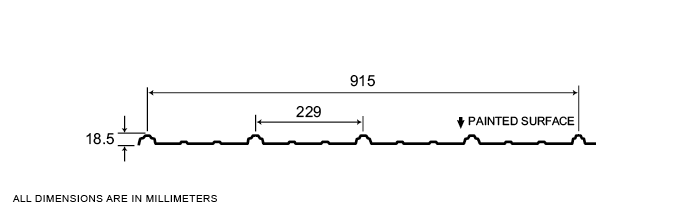

AL-315

Agway’s pre-caulked AL-315 liner panel, available in a variety of thicknesses, provides a clean interior wall surface while acting as a vapour barrier in an insulated wall system. It boasts clean, aesthetically pleasing lines and is available in a range of standard colours and finishes.

Measurement Type

Profile Picture

1. This liner sheet does not contribute to the structural performance of the panel.

2. All external loads and deflection requirements must be supported by the outer sheet.

3. Recommended usage guide:

Spans up to 6’- 0.018”

Spans 6’ to 8’- 0.024”

Spans 8’ to 10’- 0.030”

Spans over 10’-consult your sales representative

4. The prime purpose of the liner sheet is to provide a vapour barrier.

5. Oil canning may be present due to thickness and coverage. Oil canning is not a valid reason for rejection of this product.

1. This liner sheet does not contribute to the structural performance of the panel.

2. All external loads and deflection requirements must be supported by the outer sheet.

3. Recommended usage guide:

Spans up to 6’- 0.018”

Spans 6’ to 8’- 0.024”

Spans 8’ to 10’- 0.030”

Spans over 10’-consult your sales representative

4. The prime purpose of the liner sheet is to provide a vapour barrier.

5. Oil canning may be present due to thickness and coverage. Oil canning is not a valid reason for rejection of this product.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 26 | 18 | 52 | 540 | 31.5 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 22 | 18 | 1321 | 13.27 | 800 |

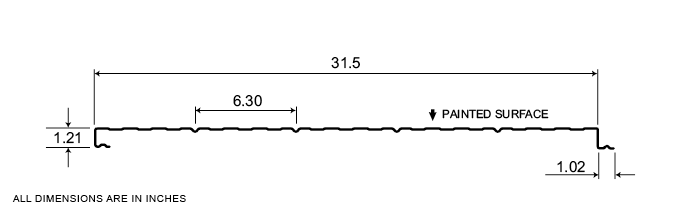

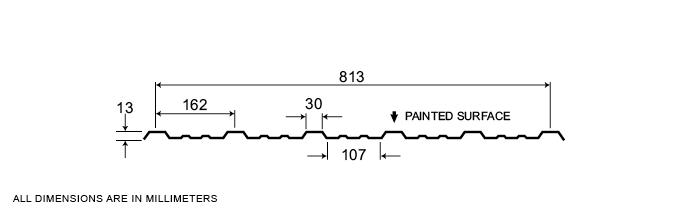

CH6-32

Available in gauges 30 to 24, our versatile CH6-32 profile can be used as wall cladding, as an interior liner, as accent striping with other contiguous profiles, or to emulate the look of a batten board cladding.

Measurement Type

Profile Picture

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

1. Steel conforms to ASTM A653.

2. Section properties are in accordance with CSA-S136-07.

3. Values in row “S” are based on strength.

4. Values in row “D” are based on a deflection limit of 1/180 of the span.

5. Web crippling not included in strength values. See example calculation in notes to designer.

6. Contact the sales department for stocked colours and gauges.

7. The load table contained on this data sheet was prepared by Dr. R.M. Schuster P.Eng. Professor Emeritus of Structural Engineering, University of Waterloo, Ontario, Canada.

Specifications

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 22 | 10 | 540 | 32 |

| GAUGE | LENGTH | COVERAGE | ||

|---|---|---|---|---|

| MINIMUM | MAXIMUM | MINIMUM | MAXIMUM | |

| 30 | 22 | 254 | 13.72 | 813 |

Section Properties

| BASE STEEL THICKNESS |

WEIGHT G90 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

SPECIFIED WEB CRIPPLING DATA(LB) |

||||

|---|---|---|---|---|---|---|---|---|---|

| in | psf | ksi | MID SPAN in 3 |

SUPPORT in 3 |

MID SPAN in 4 |

END Pe1 |

END Pe2 |

INTERIOR Pi1 |

INTERIOR Pi2 |

| 0.012 | 0.61 | 33 | 0.0116 | 0.011 | 0.0056 | 21.4 | 5.34 | 40.5 | 6.88 |

| 0.0150 | 0.68 | 33 | 0.0116 | 0.0108 | 0.0056 | 58.5 | 14.6 | 111 | 18.9 |

| 0.018 | 0.88 | 33 | 0.0208 | 0.0207 | 0.0092 | 51 | 12.8 | 96.6 | 16.4 |

| 0.024 | 1.16 | 33 | 0.0312 | 0.0304 | 0.0125 | 93.8 | 23.5 | 178 | 30.2 |

| 0.03 | 1.43 | 33 | 0.0413 | 0.0386 | 0.0156 | 150 | 37.5 | 284 | 48.2 |

| BASE STEEL THICKNESS |

MASS Z275 |

YIELD STRESS |

SECTION MODULUS |

DEFLECTION MOMENT OF INERTIA |

SPECIFIED WEB CRIPPLING DATA(LB) |

||||

|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | MPa | MID SPAN x10 3mm3 |

SUPPORT x10 3mm3 |

MID SPAN x10 3mm3 |

END Pe1 |

END Pe2 |

INTERIOR Pi1 |

INTERIOR Pi2 |

| 0.305 | 2.97 | 230 | 0.621 | 0.59 | 0.0076 | 0.315 | 0.079 | 0.597 | 0.102 |

| 0.381 | 3.3 | 230 | 0.625 | 0.58 | 0.0077 | 0.852 | 0.213 | 1.62 | 0.275 |

| 0.457 | 4.31 | 230 | 1.12 | 1.11 | 0.0126 | 0.752 | 0.188 | 1.43 | 0.242 |

| 0.61 | 5.66 | 230 | 1.67 | 1.63 | 0.0171 | 1.38 | 0.346 | 2.62 | 0.445 |

| 0.762 | 7 | 230 | 2.22 | 2.07 | 0.0213 | 2.21 | 0.553 | 4.18 | 0.711 |